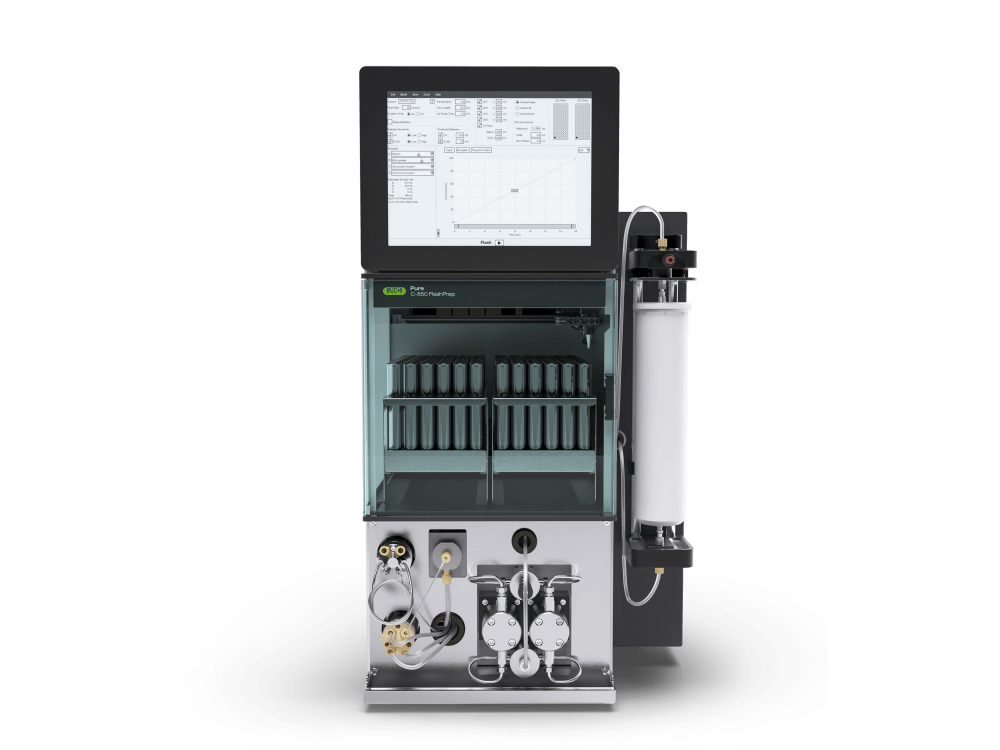

Lyovapor™ L-200

The first Freeze Dryer with Infinite-Control™

As the first freeze dryer with Infinite-Control™, the compact Lyovapor L-200 offers unparalleled automation in sublimation. Easily create and run methods, log data, record charts in real-time and interact from anywhere at anytime with mobile devices.

Features

BUCHI offers application support, trainings, preventive maintenance and IQ/OQ documentation

Use temperature difference together with optional product temperature sensors to determine the end point.

Easily read process paramenters on the adjustable display. Flexibly attach the display at the front or the side of the freeze dryer to best fit your needs.

The sample protective state is activated any time the sample temperature rises above the set collapse temperature of if the pressure falls outside of the safety range. The sample protecive state reduces the pressure, stops the shelf-heating and safeguards your precious sample.

Connect and place an additional interface outside the fume hood to control the lyophilization from outside for extra process adaptability. Work with the advanced Lyovapor™ Software after a simple upgrade to Interface Pro.

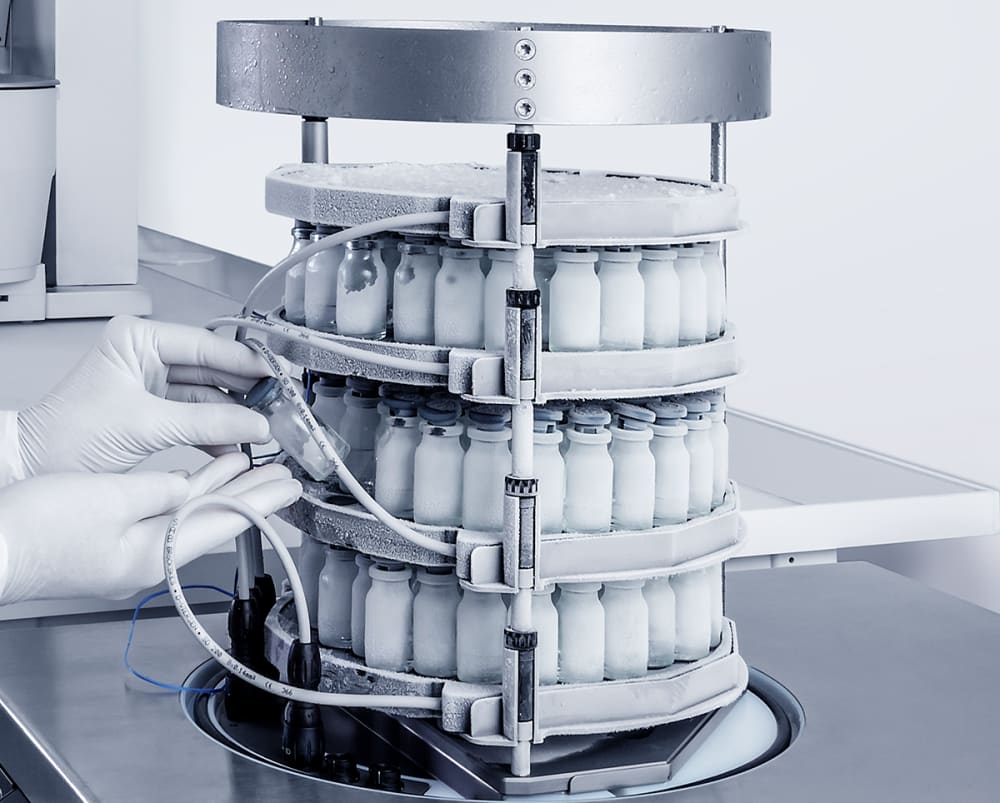

Adjust the shelf distance according to your application requirements. Link two manifold racks together for added flexibility in the lyophilization set-up.

The Lyovapor™ L-200 is an extremely high quality laboratory Freeze Drying system for a wide range of applications. The operation of the Freeze Dryer and the drying of all kinds of different samples are straightforward.Prof. Dr. Heiko A. Schiffter-Weinle - Department of Galenics, TH Köln/University of Applied Sciences

Downloads

- Operation Manual Lyovapor L-200 / L-200 Pro en(pdf)

- Technical Data Sheet Lyovapor L-200(pdf)

- Solution Brochure Freeze Drying en(pdf)

- Product Brochure Lyovapor L-200 en(pdf)

- Product Brochure Pharma and Chemistry en(pdf)

Related Instruments

Related Courses & Trainings

Applications

From standard application to unlimited ice capacity

Education

For a wide range of applications in academic education: Complete temperature sensitive drying.

Biotechnology

Used in biotechnology development for drying biologically active products: Drying and stabilization of small quantities in micro titer plates or small flasks.

Environmental Analysis

Required for sample preparation and stabilization to monitor environmental pollution: During storage of samples in order to destroy micro-organisms. Drying, e.g. for SpeedExtractor.

Chemical

For gentle and lossless drying in QC and R&D laboratories: Drying of most minute quantities in micro titer plates as well as small and large flasks or bulk drying is possible.

Food and Natural Extracts

Used for developing function-al food and analytics: Solvent is removed during, drying without destroying, the natural substances such as proteins, minerals or vitamins.

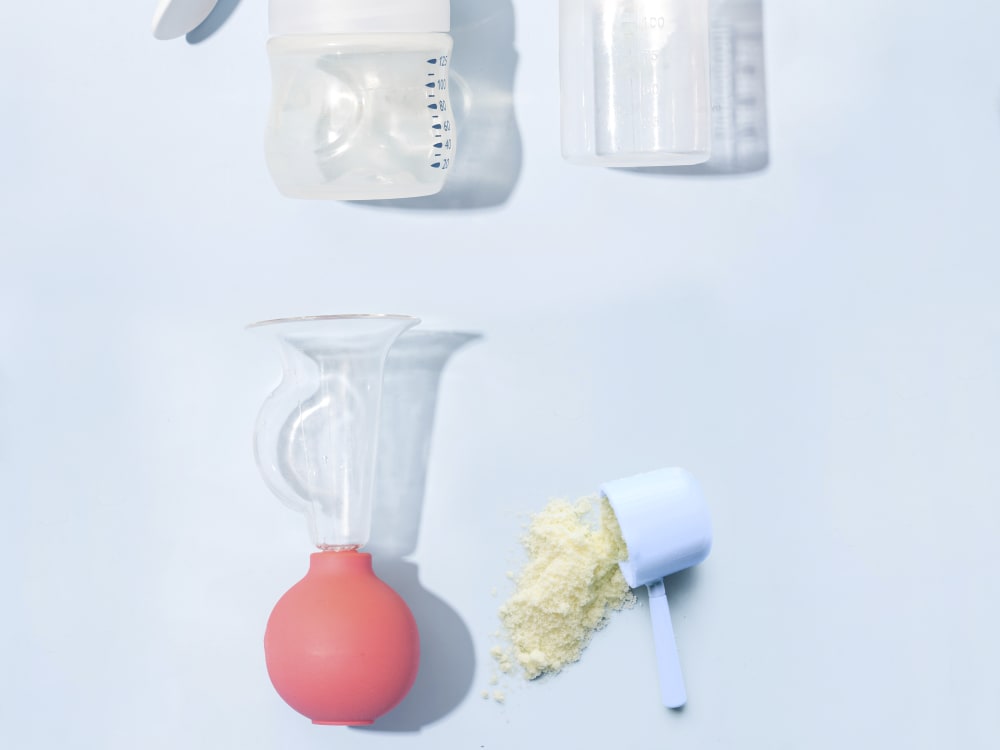

Pharmaceutical

For various applications in QC as well as laboratory scale synthesis and formulation in R&D departments: Drying of peptides and proteins of amorphous and crystalline solutions.