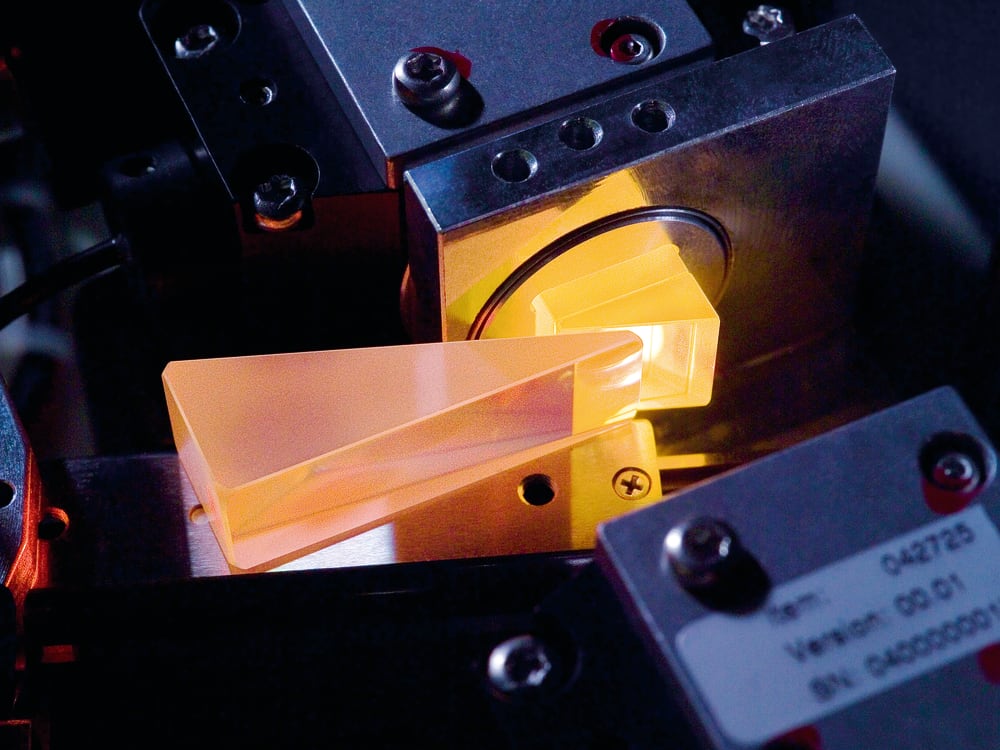

Rotavapor® R-250 Pro

Best performance at the highest safety

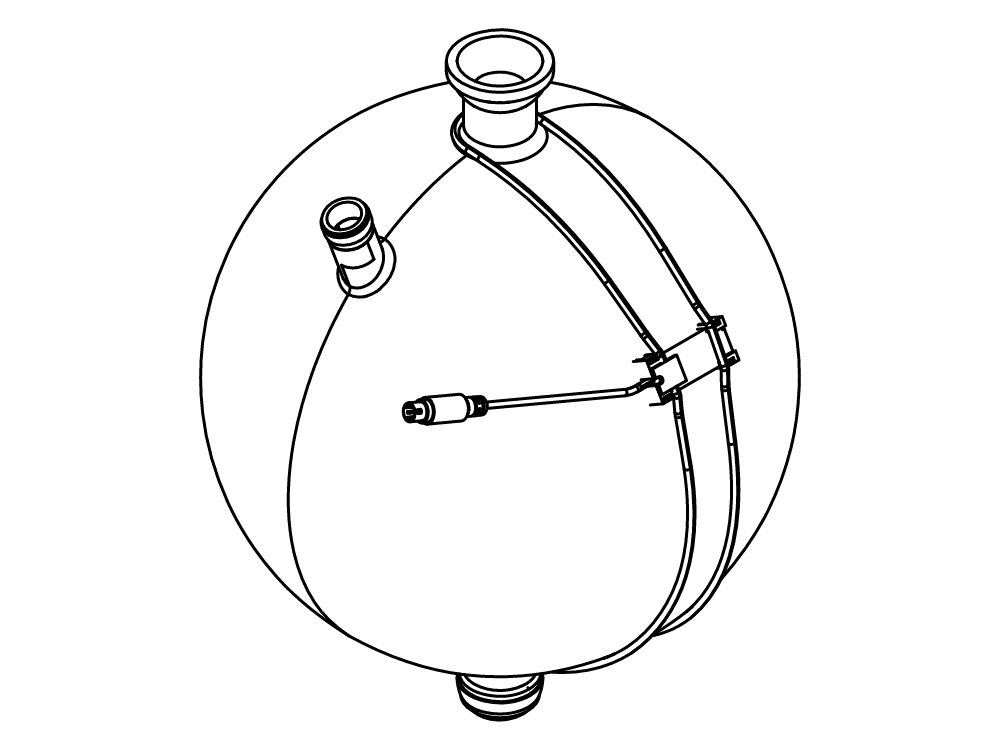

The Rotavapor® R-250 Pro is designed to fulfill a wide range of distillation applications in the industrial environment. Safety, robustness and easy handling are the key benefits of this system. Different glass configurations and a wide range of accessories guarantee the perfect setup for maximum performance and automation grade.

Features

Premium quality materials are used for the robust design of the Rotavapor R-250 Pro. You can work under harsh production conditions without compromising the long lifetime of the product.

The intuitive interface allows you to have access to all process parameters with a comprehensive overview of settings, current readings, and progression graph.

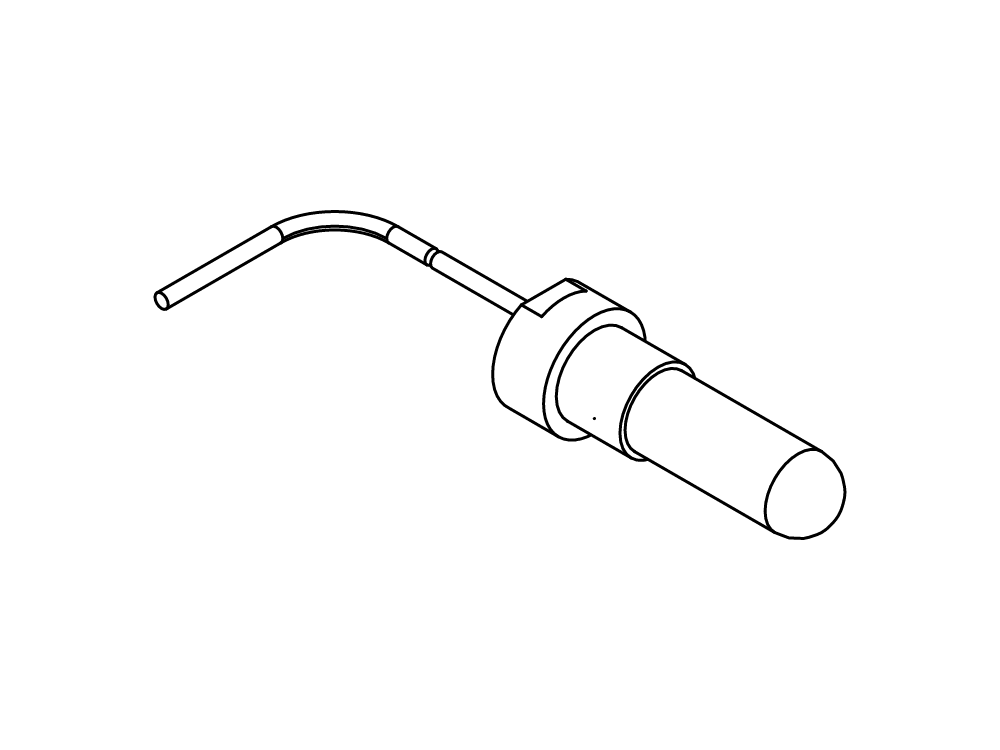

If you require automation, our sensor technologies with foam, level and cooling temperature sensors will allow you to have unattended distillation. Remote monitoring and control is made possible with our OpenInterface and BUCHI Cloud Services.

Our robust design and the safety features, such as plastic coated glass (P+G), over-temperature protection, over-pressure release, bath overflow drain and spring-supported valves, ensure maximal safety.

Program your customized standard operating procedures (SOPs) on the Interface I-300 Pro for convenient user guidance through the process.

Rotary evaporator is a basic requirement of any chemistry laboratory. The name BUCHI is synonymous with this application mainly because of their quality product and ruggedness of these equipments. Various models are available for special applications/requirements. These are very useful not only in laboratory but also in production activity particularly on pilot scale/ kilo lab scaleK. S. Bhide - AstraZeneca Pharma India Ltd.

Related Parts & Accessories

Downloads

- Technical Data Sheet Rotavapor R-250 Pro(pdf)

- Operation Manual Rotavapor R-250 Pro en(pdf)

- Operation Manual Recirculating Chiller F-360 en(pdf)

- Installation Manual automatic bath replenishment(pdf)

- Installation Manual Level Sensor en(pdf)

- Installation Manual Rotavapor® R-250 Pro with Vacuum pump Edwards nXDS 10iC(pdf)

Related Instruments

Related Courses & Trainings

Applications

Benefit from decades of expert knowledge

Chemical

In the chemical industry a wide range of applications can be performed with an industrial Rotavapor®: Concentration, Drying, Solvent Recycling.

Academia

Solvent re-use plays an important role in Academia. The Rotavapor® is the best choice for this and many other applications: Concentration, Solvent recycling, Distillation.

Pharmaceutical

The pharmaceutical industry has a need for an evaporation solution that covers a wide range of applications. The rotary evaporator is the best choice for gentle evaporation: Concentration, Drying, Re-crystallization, Synthesis.