Rotavapor® R-220 EX

EX-protection fulfilling highest safety levels

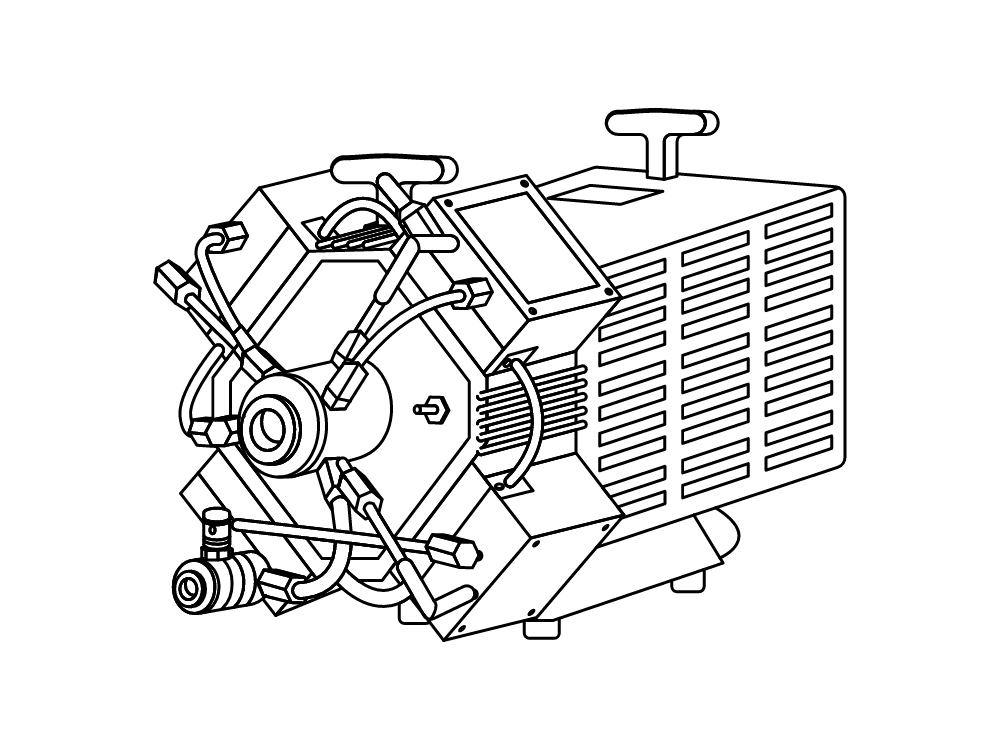

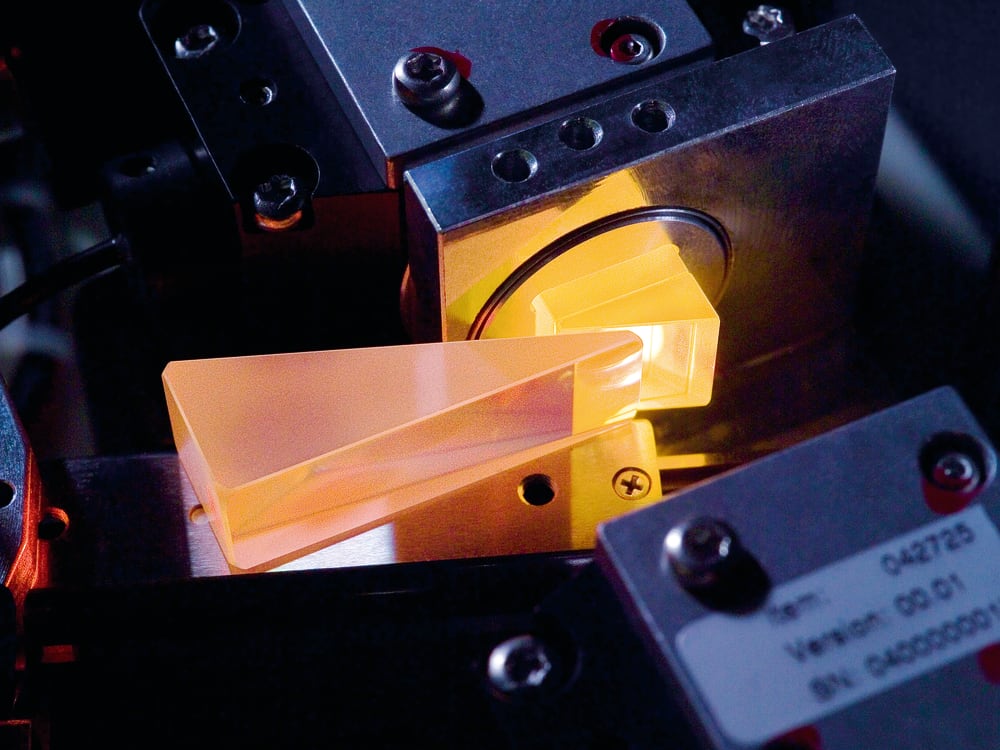

The Rotavapor® R-220 EX is the EX rated version of the Rotavapor®R-220 Pro and fulfills the high requirements of the ATEX regulations. It is designed for easy and safe operation combined with high performance.

Features

To ensure an intensive use under rough conditions, BUCHI provides you with instruments characterised by robust design and top quality.

As high-throughput is important, we offer distillation rates up to 12 L of Ethanol per hour with the R-220 EX

The use of top quality inert materials guarantees a long lasting operation and protect your substance.

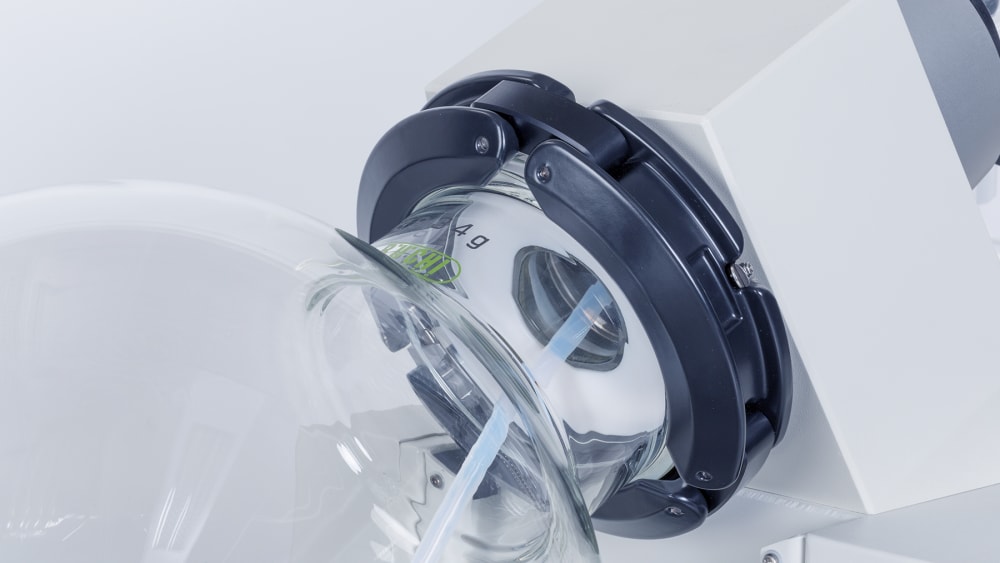

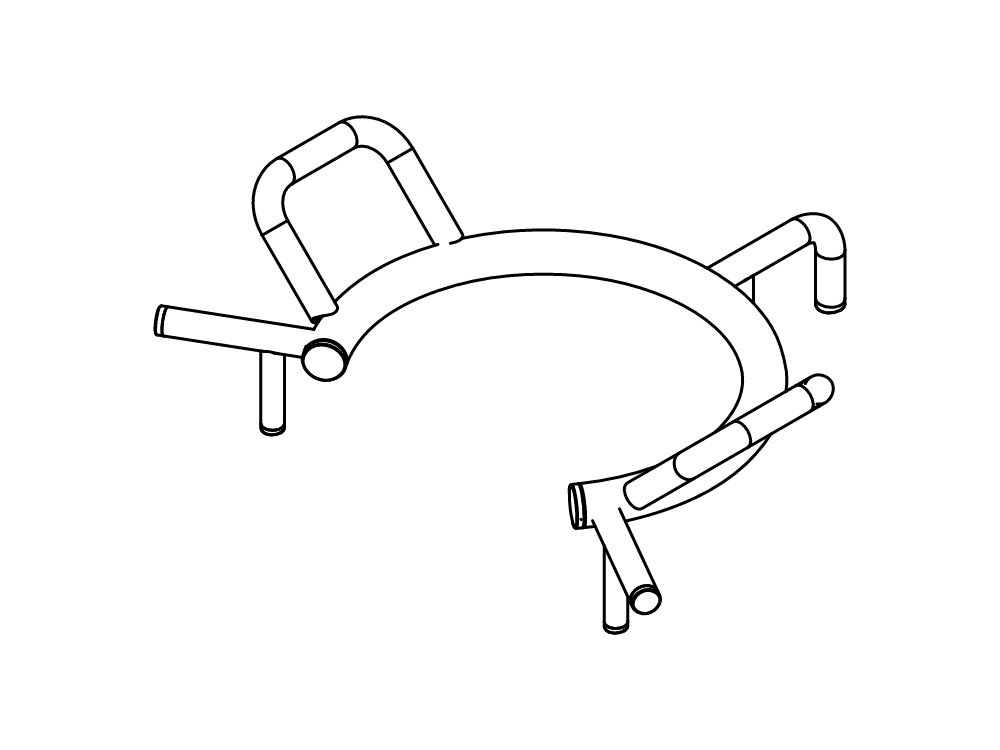

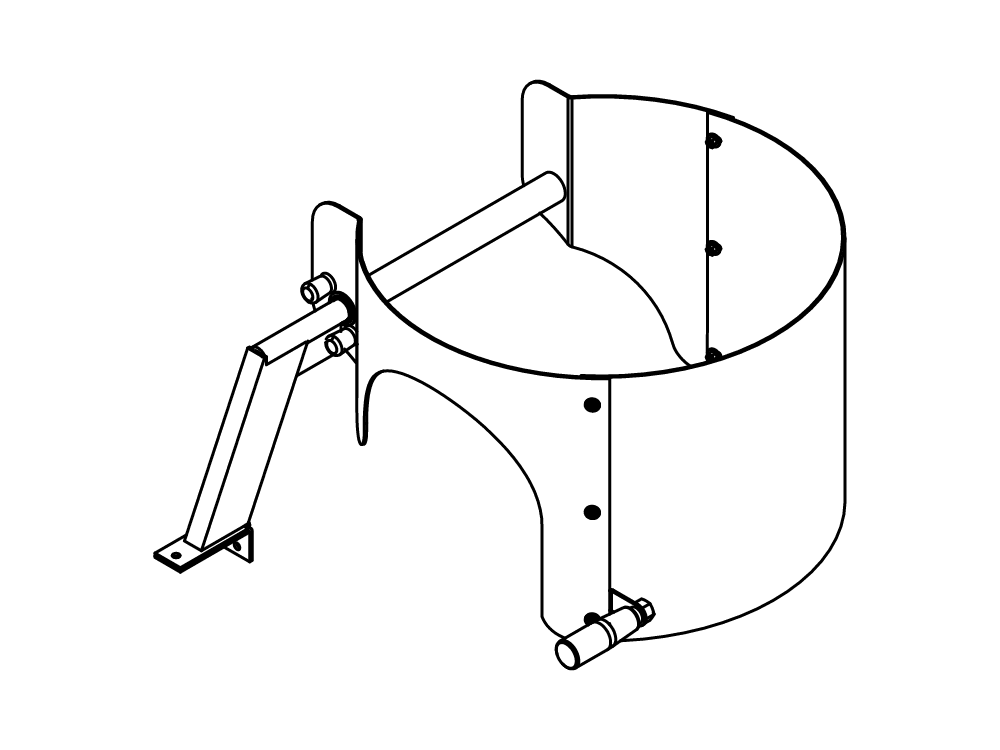

The easy and self-explanatory controls ensure a safe and troublefree process. The optional flask handler guarantees a safe one person operation.

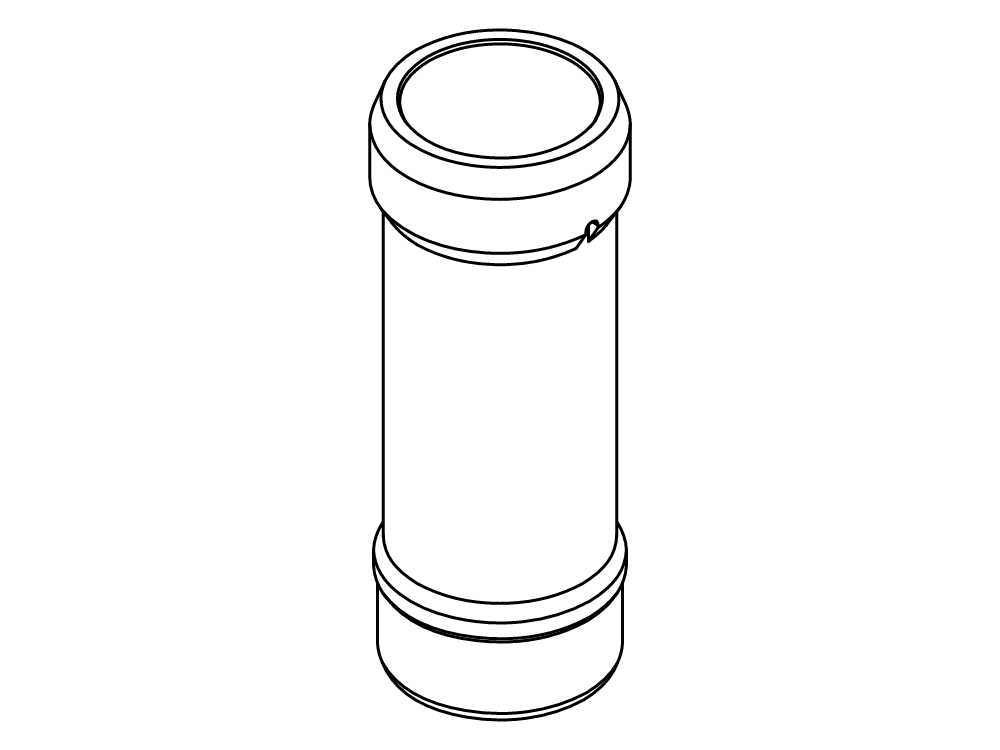

With a wide range of available glass assemblies, we are able to offer the perfect solution for efficient and gentle distillation of your product.

An intensive cooperation with external experts ensures that the Rotavapors® comply with the latest regulations.

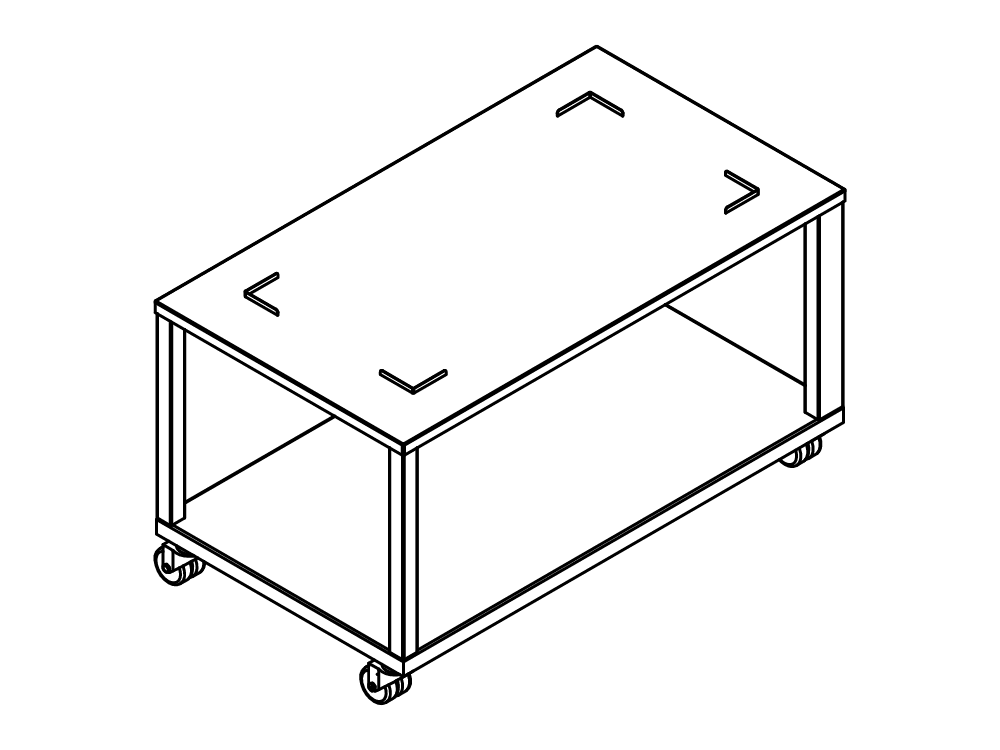

Related Parts & Accessories

Downloads

- Technical Data Sheet Rotavapor R-220 EX(pdf)

- Product Brochure Rotavapor R-220 EX / R-250 EX en(pdf)

- Operation Manual Rotavapor R-220 EX en(pdf)

- Installation Manual 10L Adapter for flask handler(pdf)

Related Instruments

Related Courses & Trainings

Applications

Benefit from decades of expert knowledge

Chemical

In the chemical industry a wide range of applications can be performed with an industrial Rotavapor®: Concentration, Drying, Solvent Recycling.

Academia

Solvent re-use plays an important role in Academia. The Rotavapor® is the best choice for this and many other applications: Concentration, Solvent recycling, Distillation.

Pharmaceutical

The pharmaceutical industry has a need for an evaporation solution that covers a wide range of applications. The rotary evaporator is the best choice for gentle evaporation: Concentration, Drying, Re-crystallization, Synthesis.