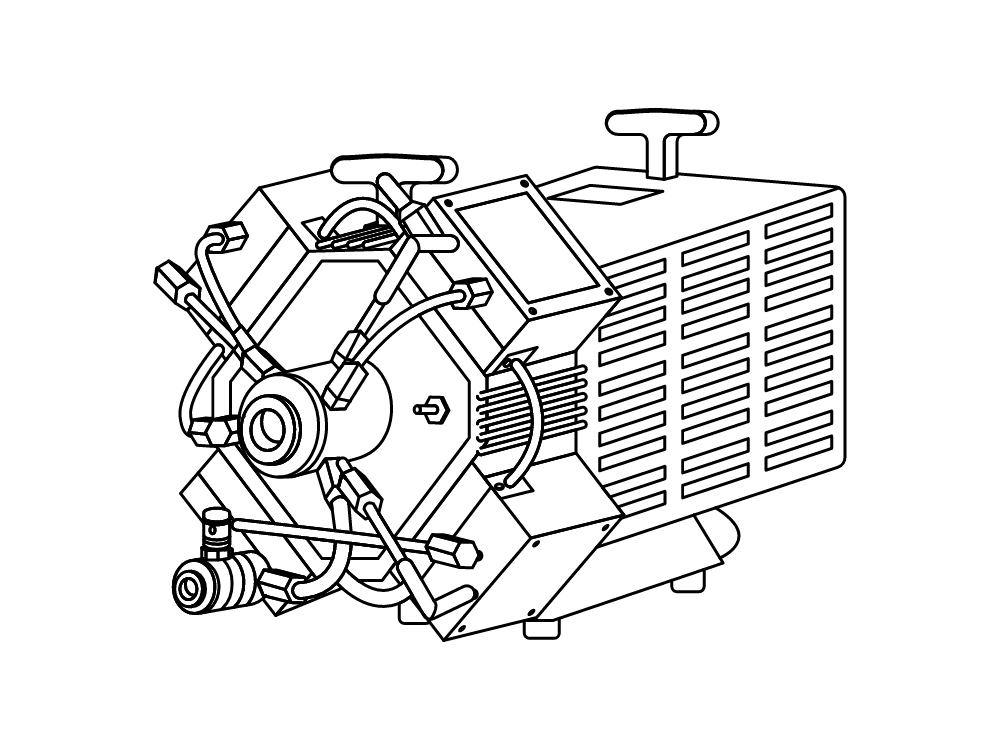

Rotavapor® R-250 EX

EX-protection fulfilling highest safety levels

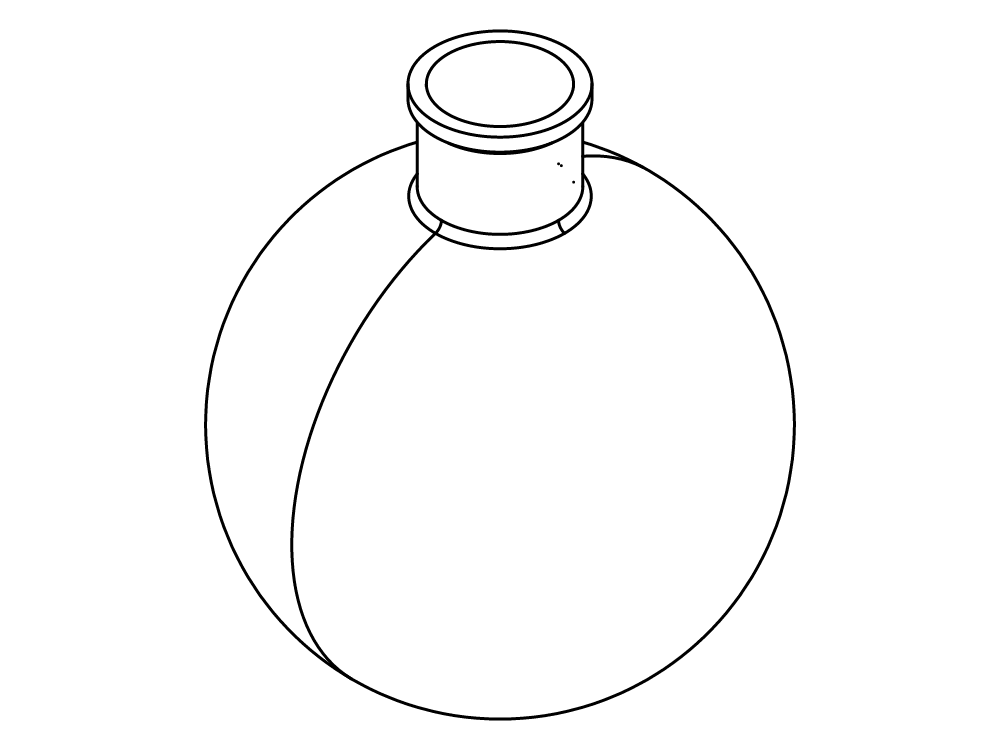

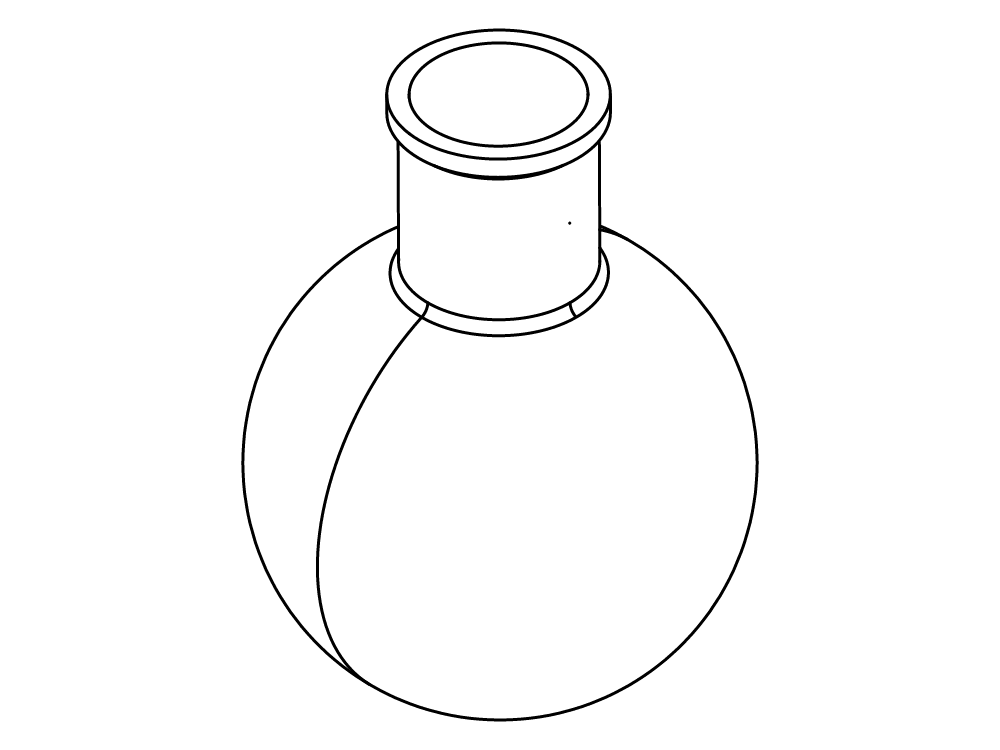

Intuitive operation and handling guarantee safe and efficient industrial distillation. Customize your Rotavapor® R-250 Ex to your needs. Meeting the newest EX regulations, you are always on the safe side for distillation with a flask size of up to 50 liters.

Features

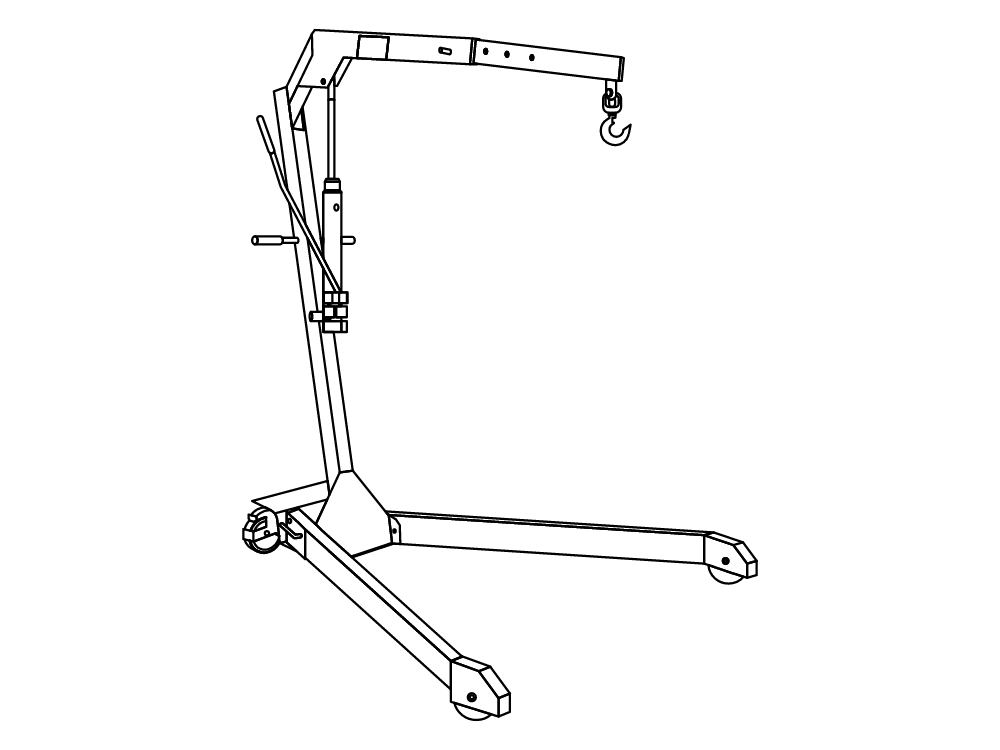

BUCHI offers a robust system to allow an easy and intensive use even under harsh conditions. Your Rotavapor® R-250 EX long lifetime is ensured thanks to smart system design.

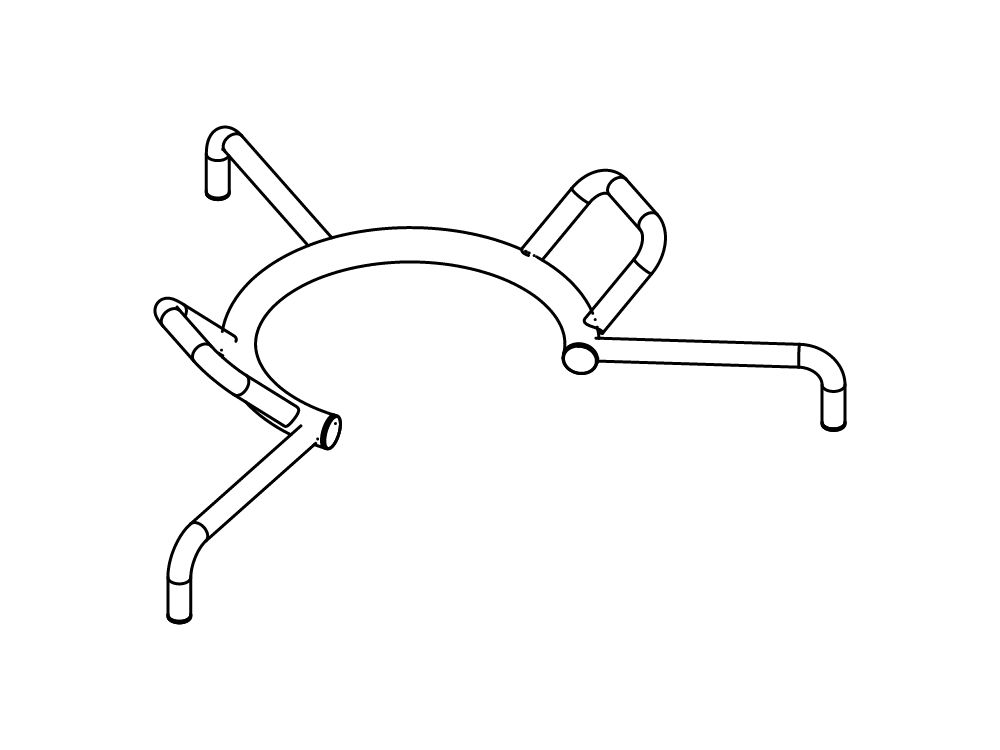

Easily find the optimal setup for your application thanks to a broad variety of glass assemblies offered by BUCHI.

The ethanol distillation rate with the rotary evaporator R-250 EX can reach up to 19 L per hour.

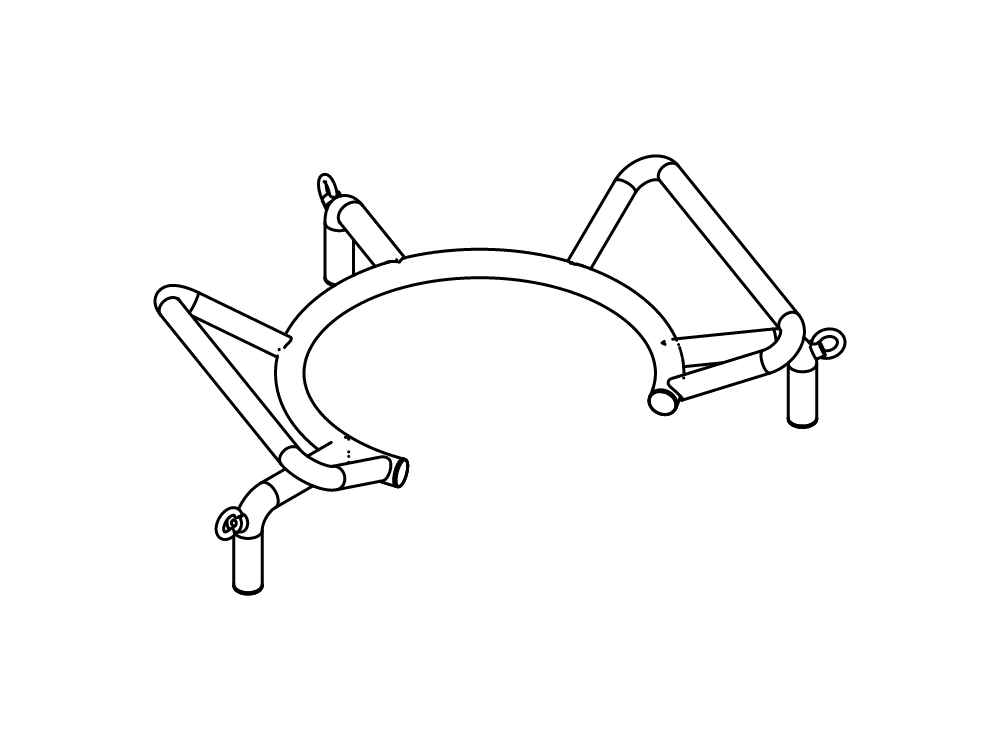

With an easy and intuitive control panel, BUCHI ensures your fast and easy system operation. By adding a flask handler to your configuration, you avoid the hassle and difficulties of handling your 50 L evaporating flask.

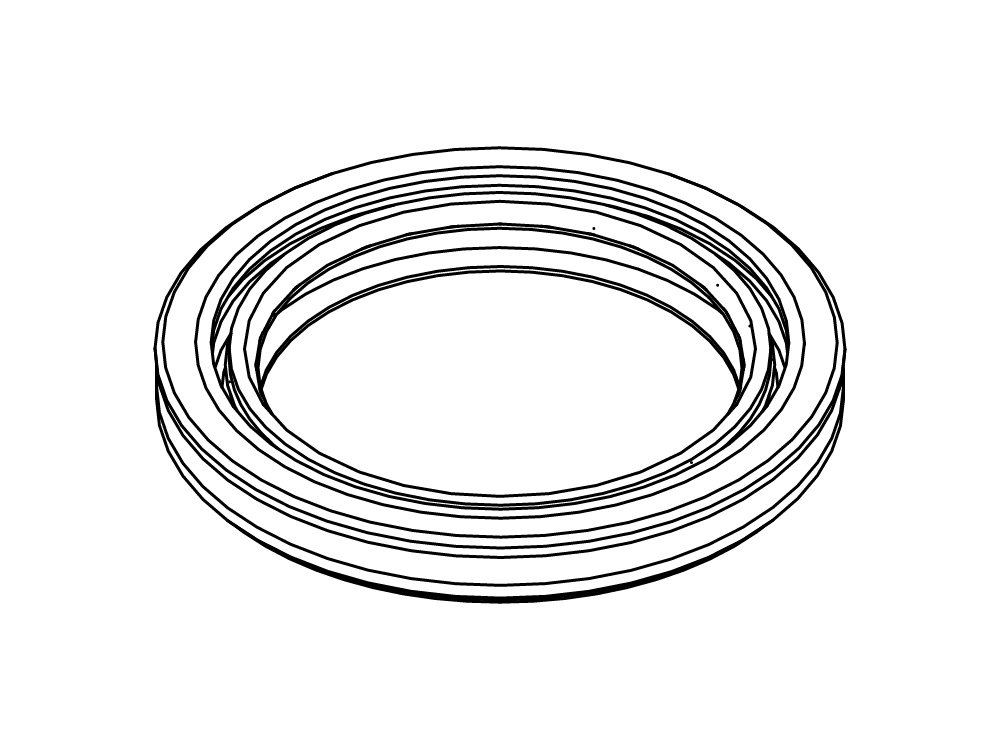

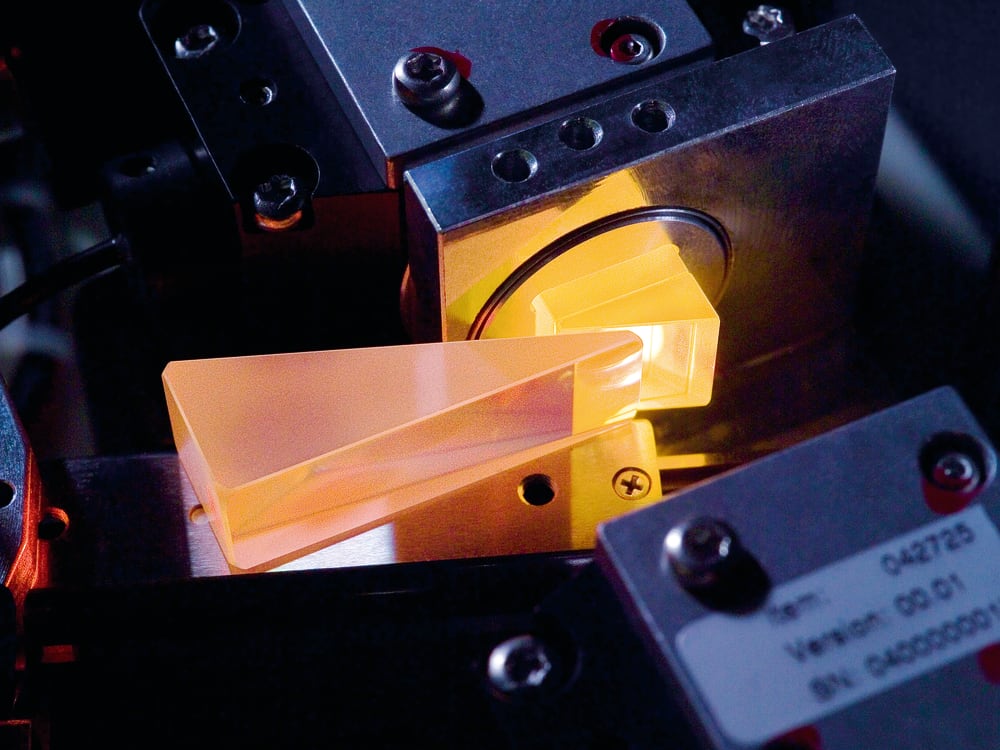

BUCHI uses inert material with superior quality to gurantee the quality of your results.

The Rotavapor® EX certification complies with current stringent regulations. BUCHI has a close collaboration with experts in the field in order to offer the best and safest solutions.

Related Parts & Accessories

Downloads

- Technical Data Sheet Rotavapor R-250 EX(pdf)

- Product Brochure Rotavapor R-220 EX / R-250 EX en(pdf)

- Operation Manual Rotavapor R-250 EX en(pdf)

Related Instruments

Related Courses & Trainings

Applications

Benefit from decades of expert knowledge

Chemical

In the chemical industry a wide range of applications can be performed with an industrial Rotavapor®: Concentration, Drying, Solvent Recycling.

Academia

Solvent re-use plays an important role in Academia. The Rotavapor® is the best choice for this and many other applications: Concentration, Solvent recycling, Distillation.

Pharmaceutical

The pharmaceutical industry has a need for an evaporation solution that covers a wide range of applications. The rotary evaporator is the best choice for gentle evaporation: Concentration, Drying, Re-crystallization, Synthesis.