Interface I-300 / I-300 Pro

Central control of all process parameters

The interfaces are easy to use panel to regulate the vacuum. It is also the central control unit for all process parameters (for I-300/I-300 Pro). They increase efficiency and convenience of rotary evaporation processes.

Features

With the AutoDest function and the foam sensor even foaming samples can be distilled automatically.

All process parameters are graphically displayed to facilitate the supervision of the distillation.

Convenient water-resistant touch panel, user-friendly navigation knob and instant stop button.

Your process is fully traceable as all parameters are continuously recorded by Interface I-300 / I-300 Pro. Export the set of data on an SD card for further analysis.

Operate the interface from the most convenient location thanks to flexible installation on a fume hood with an additional holder.

The BUCHI Monitor App for iOS, Android and Windows offers live view and charting of all process parameters and includes push notifications.

The drying mode alternates rotation direction in user-defined intervals over a set time period to enhance drying solids.

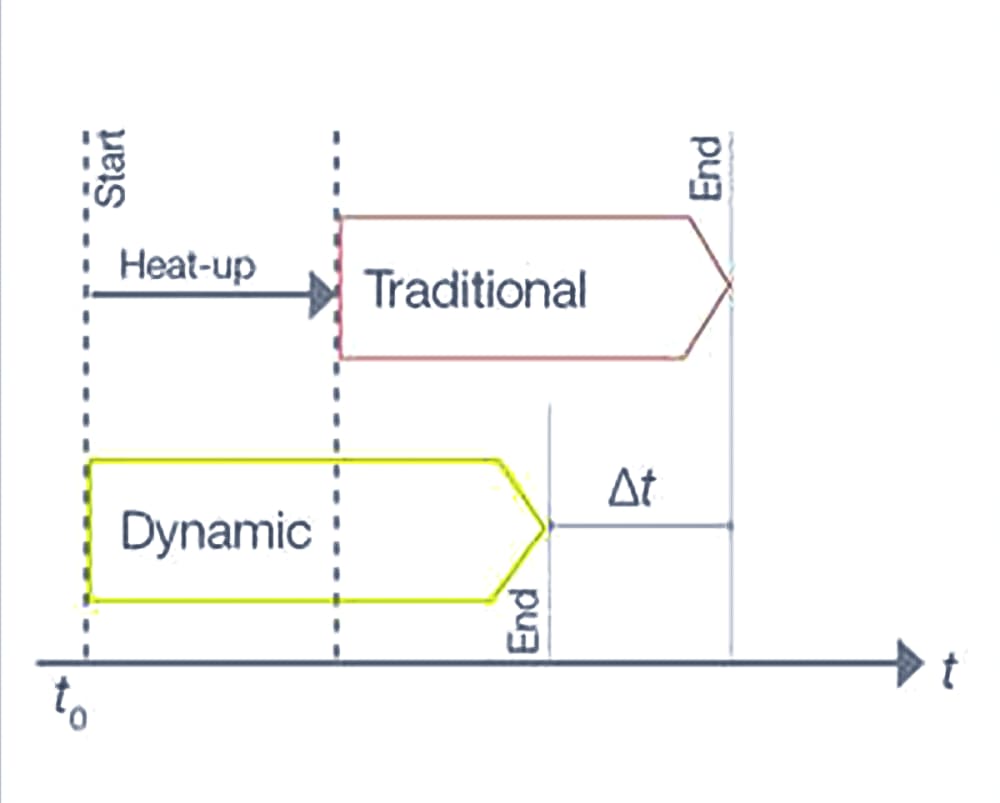

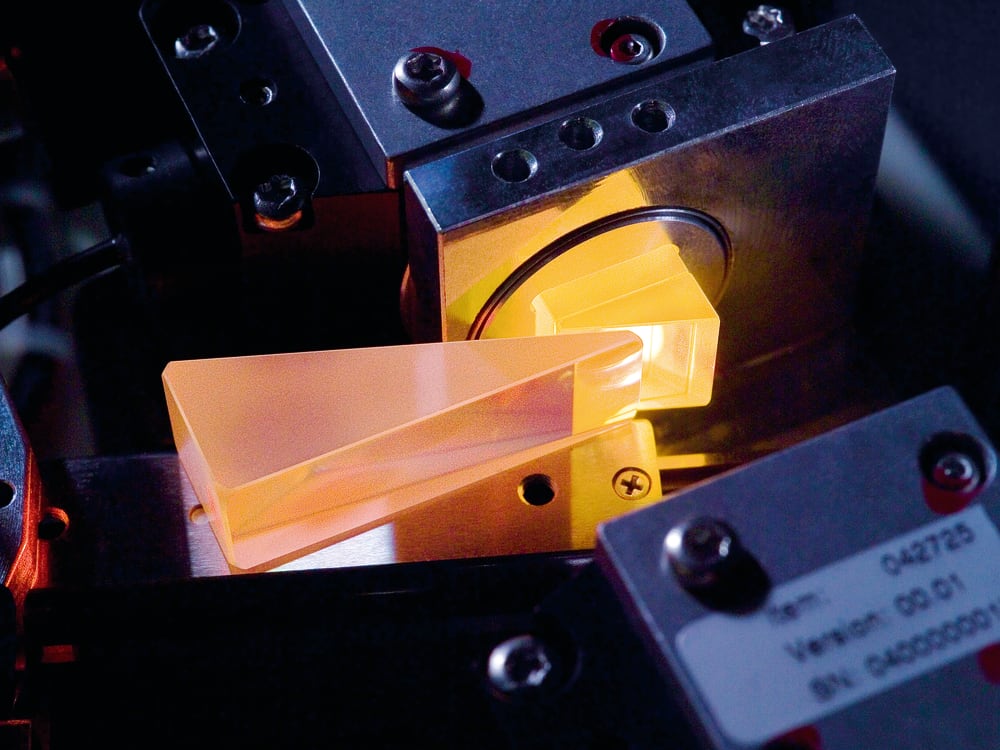

The distillation process starts directly after choosing the solvent from the library. The vacuum is dynamically adjusted while chiller and bath reach their set temperature.

Preferred solvents, leak test and other functions can be saved as favorites for quick access.

Convenient and user-friendly navigation knob, four function keys for quick access and overall stop.

An integrated test checks the tightness of the system and displays the result.

Compare the Interface I-300 / I-300 Pro

Related Parts & Accessories

Downloads

- Technical Data Sheet Interface I-300 / I-300 Pro(pdf)

- Product Brochure Interface I-300 en(pdf)

- Product Brochure Interface I-300 Pro en(pdf)

- Operation Manual Interface I-300 Pro en(pdf)

- Operation Manual Interface I-300 en(pdf)