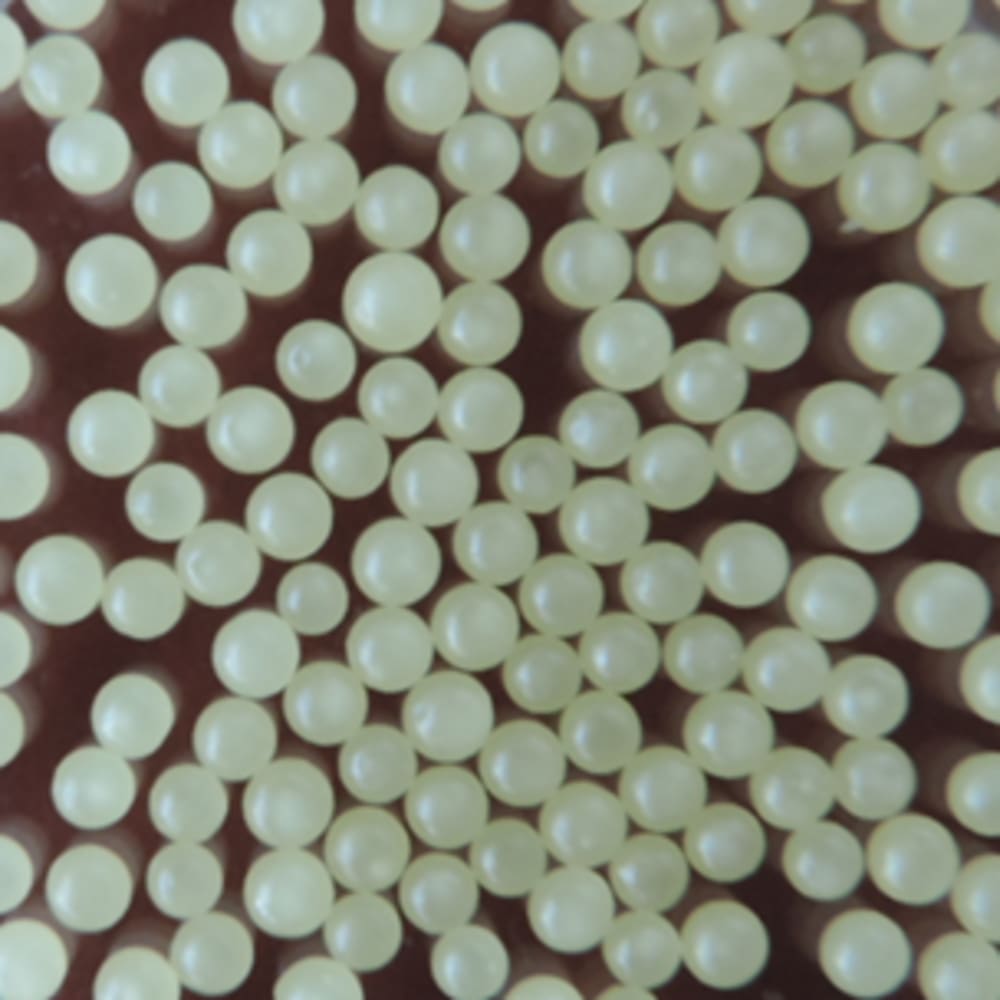

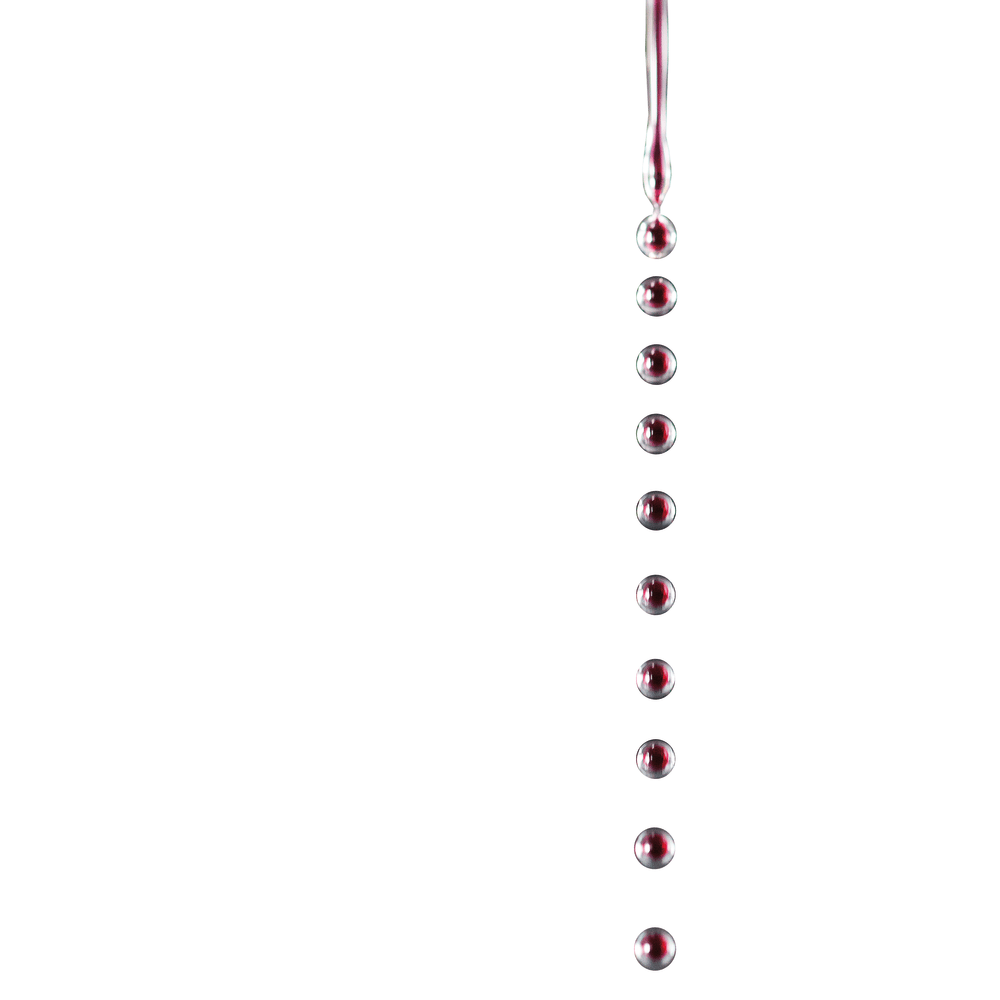

Uniform and dry SiO2 beads with the Encapsulator

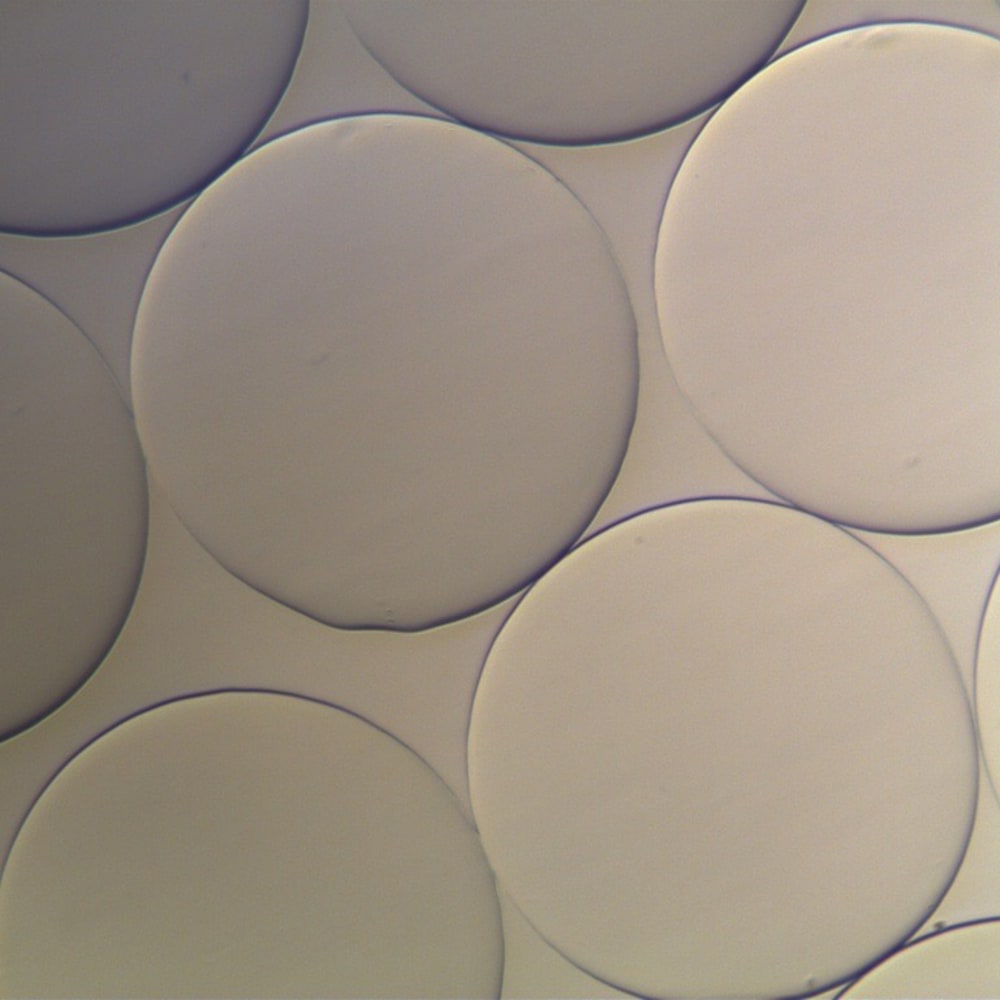

Encapsulator B-390 / B-395 Pro: Manufacturing of dry spherical monodisperse SiO2 beads with a size of 430 μm

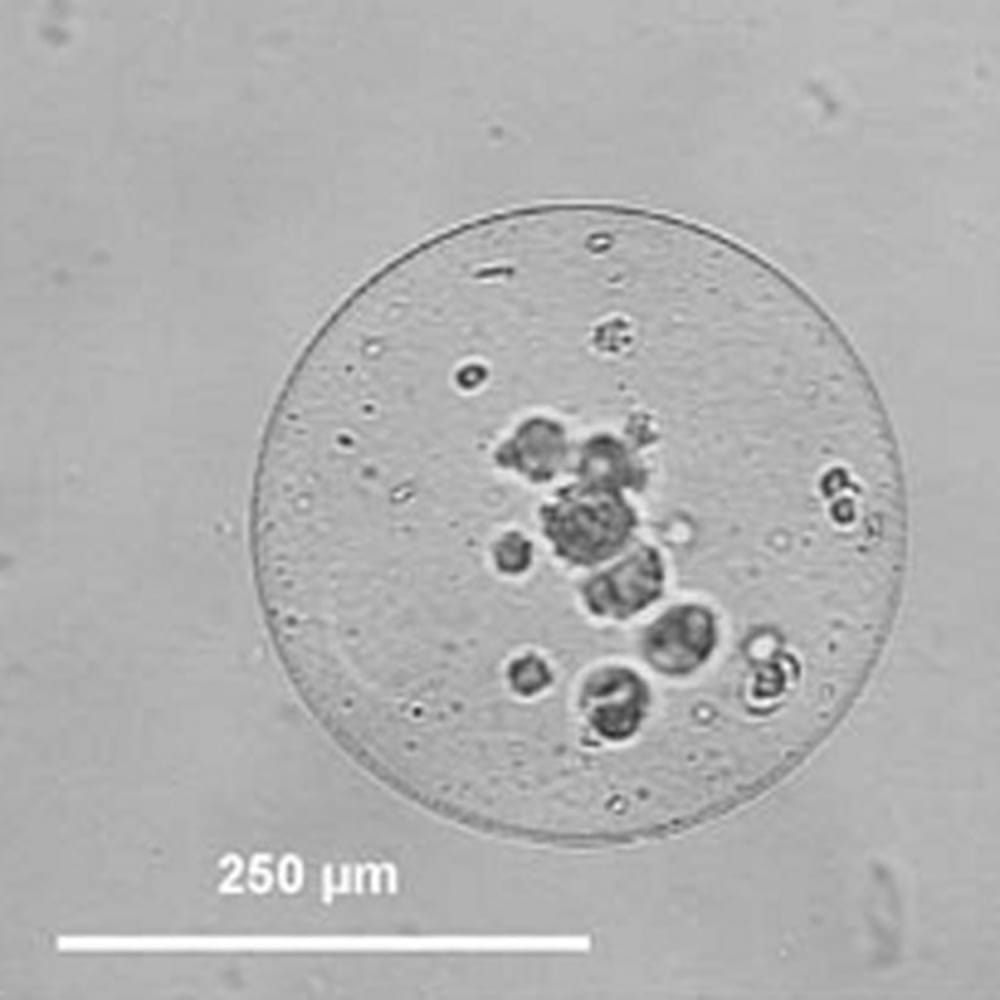

Advanced ceramic materials are of high interest due to their specific and favorable properties such as hardness, durability, optical behavior compared to traditional materials. SiO2 among other oxides such as Al2O3, TiO2 and ZrO2, are common raw materials. In the manufacturing process of advanced materials, granulation is one of the important steps. Usually, large and uniform particles are desired.This application note describes the production of spherical and uniform SiO2 beads having an average size of approximately 430 μm in diameter. The Encapsulator B-395 Pro was applied to obtain and the Rotavapor® R-300 to dry the beads. Using the presented technique, the particle size of the final beads can be varied in the range between 300 and 1000 μm.

S'inscrire pour télécharger

Instruments correspondants

Applications similaires

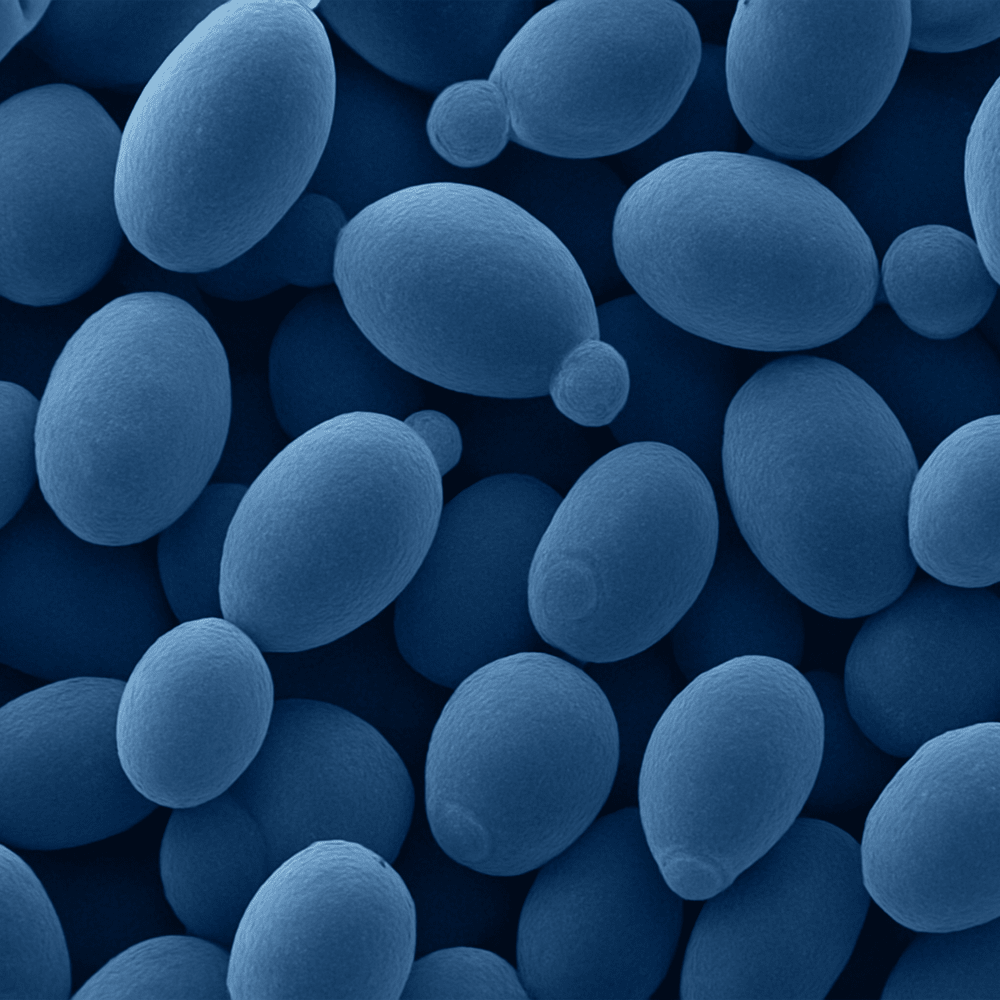

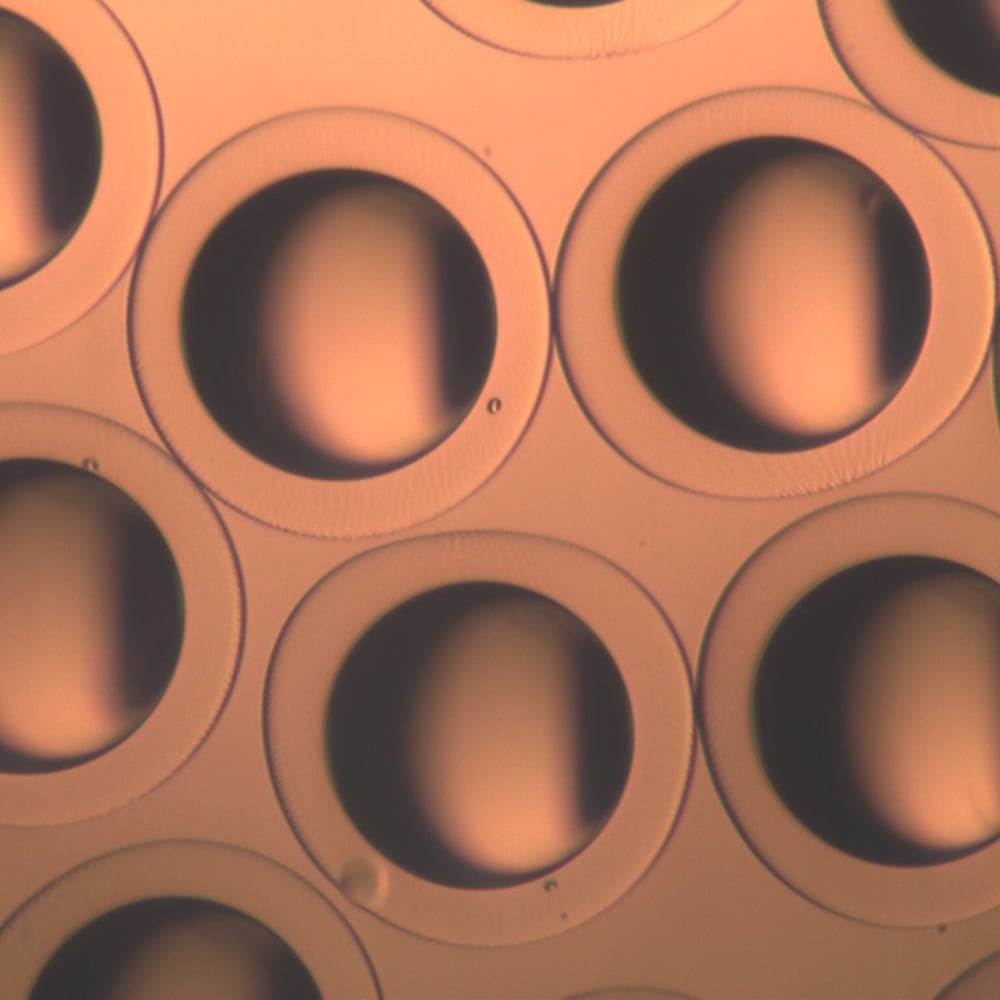

Freeze drying of beads containing yeasts

The cell viabilities of microorganisms during storage are of economic importance for probiotic dietary food and feed supplements. By combining granulation and freeze drying, dust free particles homogeneous in size and composition can be obtained. This will enable a good particle flowability, an easier dosage and a faster reconstitution of the product can be obtained. Encapsulator as a granulator to prill the yeasts suspension into liquid nitrogen and form monodispersed beads that will then be freeze dried.