Recirculating Chiller F-305 / F-308 / F-314

The efficient way of cooling

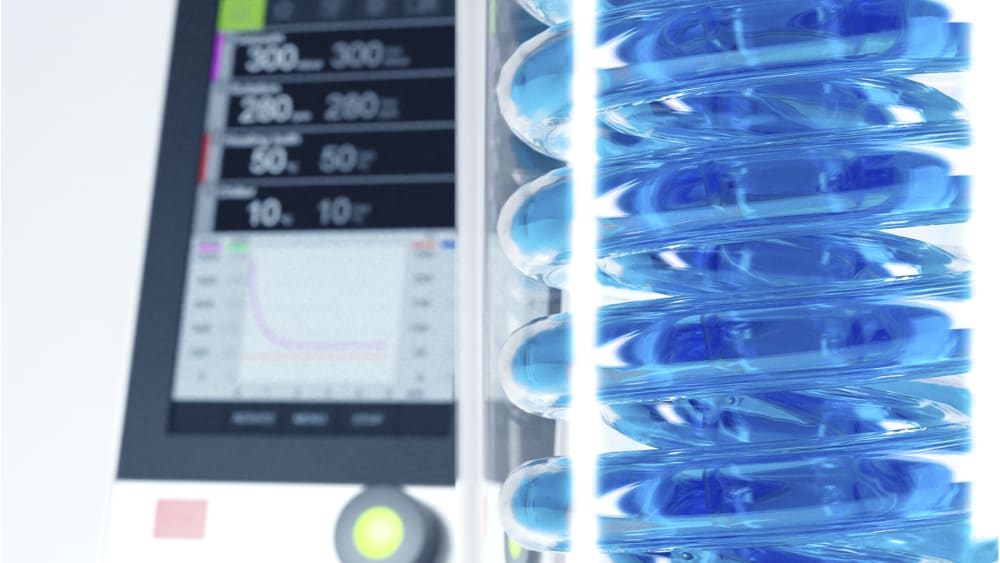

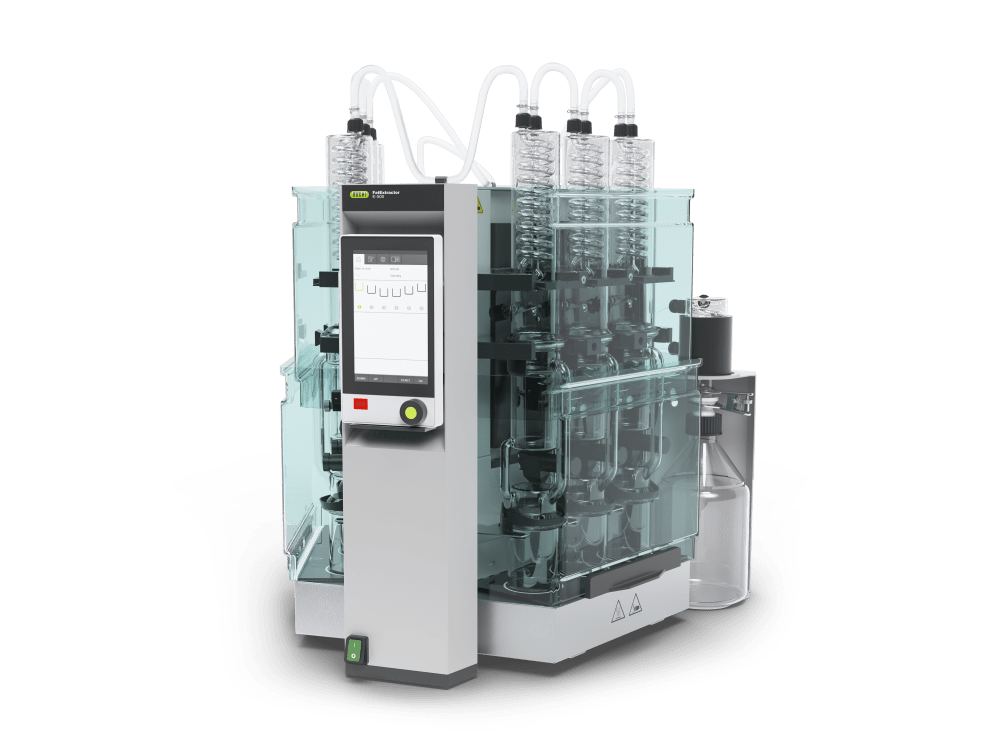

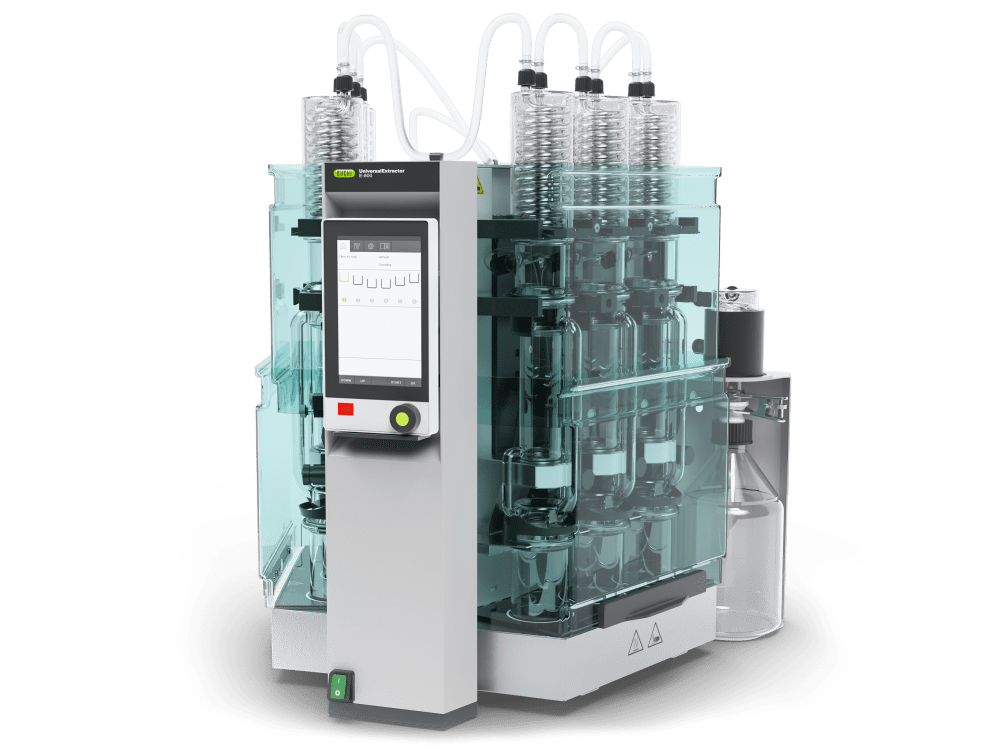

The efficient way of cooling during evaporation, extraction or Kjeldahl comes courtesy of the Recirculating Chiller F-305 / F-308 / F-314. Combine with the Rotavapor® R-300 to gain more automation, more accuracy and more energy and time savings.

Features

Convenient temperature setting and control when integrated in a Rotavapor® R-300 system.

The ECO-mode in conjunction with the interface saves energy and reduces heat emission by switching into a stand-by mode when not in use.

Operating with a Rotavapor® R-300 system, the vacuum is automatically adjusted to the heating and cooling temperature, maximizing the distillation performance.

Conveniently set the cooling temperature directly on the chiller or on the central Interface I-300 / I-300 Pro.

The chiller consists of a circuit system with a closed loop so that the same coolant is used all the time to eliminate waste, improve sustainability and increase cost-efficiency.

Compare the Recirculating Chiller F-305 / F-308 / F-314

Downloads

- Operation Manual Recirculation Chiller F-305 / F-308 / F-314 en(pdf)

- Technical Data Sheet Recirculating Chiller F-305 / F-308 / F-314(pdf)

- Product Brochure Recirculating Chiller F-305 / F-308 / F-314 en(pdf)

- Solution Brochure Environmental Analysis en(pdf)

- Solution Brochure Parallel Evaporation en(pdf)

- Solution Brochure Digestion and Distillation en(pdf)