Determination of hexachlorocyclohexane isomers and chloro substituted benzene congeners in air

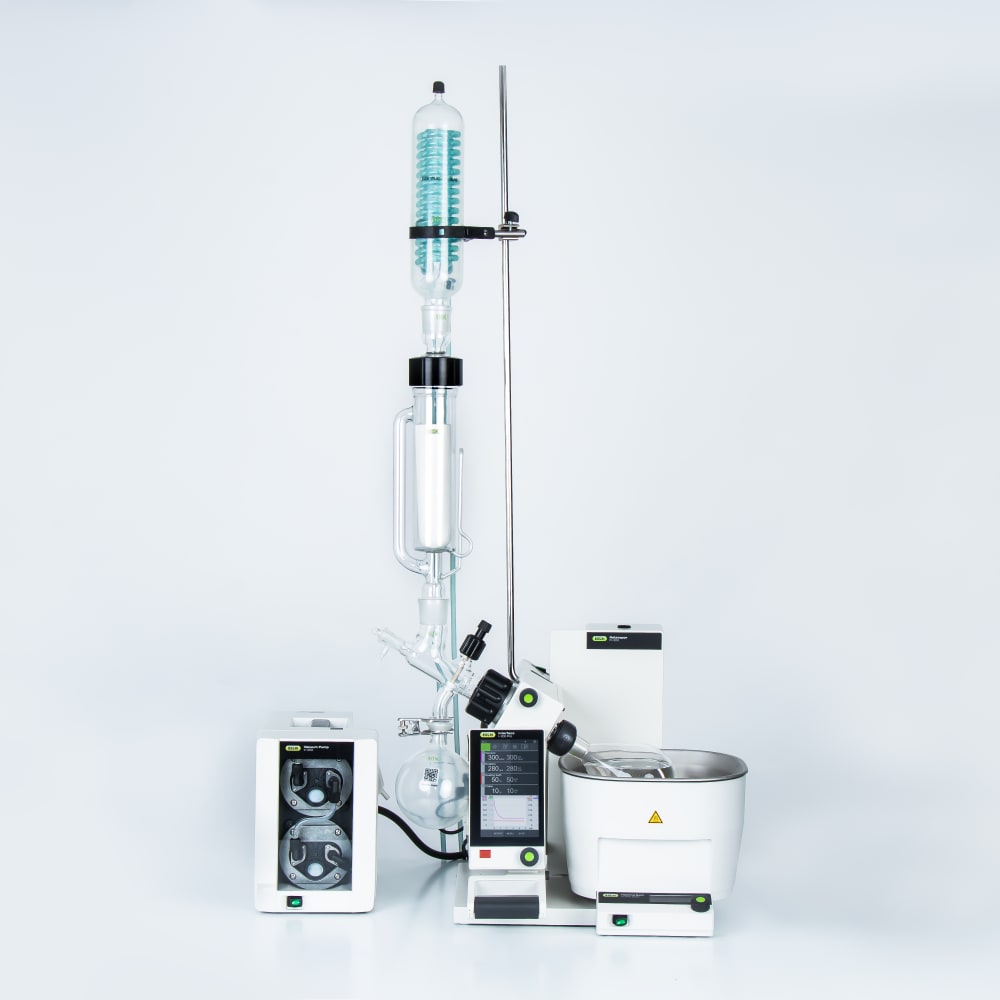

Syncore® Analyst R-12, Residual volume 1.0 mL, Vacuum Pump V-300, Interface I-300 Pro, Recirculating Chiller F-314, Flushback module R-12: Time saving concentration and reproducible recovery rates of volatile analytes.

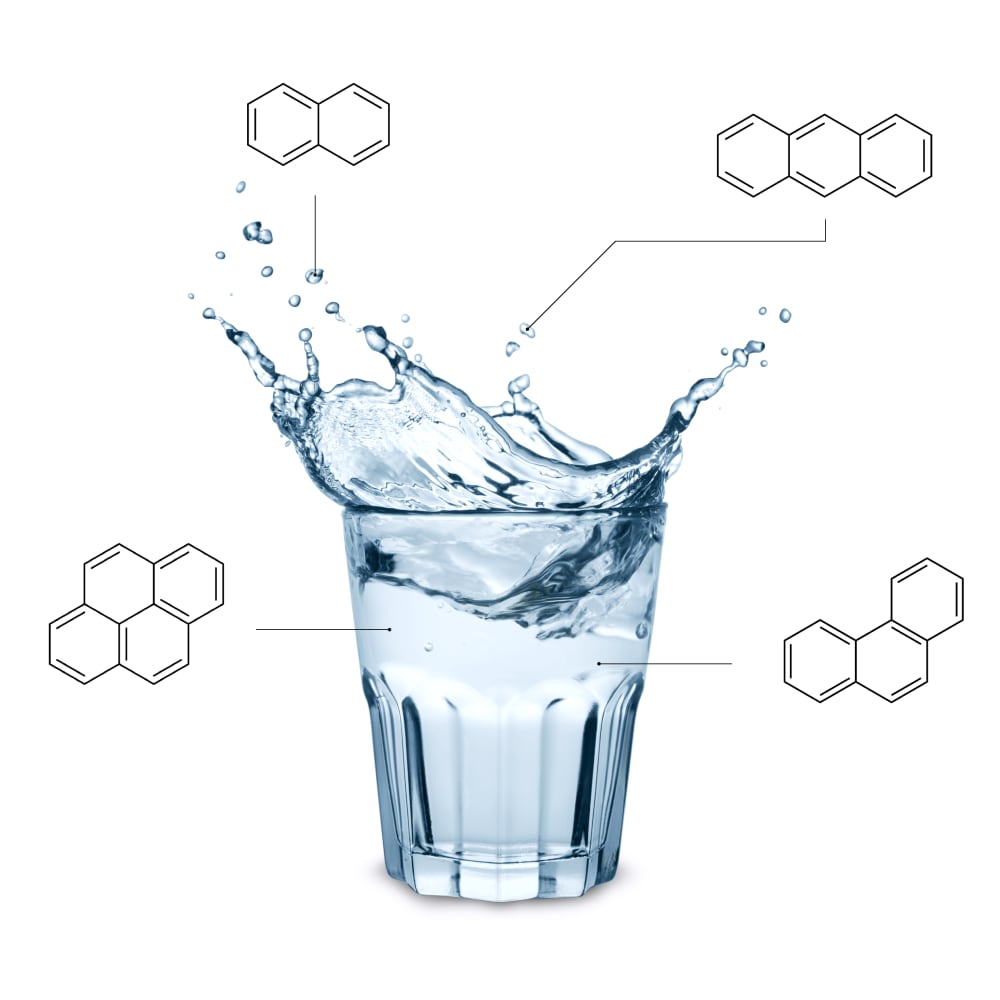

TKN determination in water and wastewater

SpeedDigester K-439, Kjel Line and MultiDist: Steam distillation and Potentiometric determination of Total Kjeldahl Nitrogen (TKN) according to the Kjeldahl method in water and wastewater along with determination of Limit of Detection (LOD) and Limit of Quantification (LOQ).

Your Evaporation Guide – Immersion angle

Achieve higher distillation efficiency when using a rotary evaporator by reading on the impact of immersion angle.

The evaporation rate of a rotary evaporator depends to a large extend on the immersion angle of the evaporating flask. The flatter the immersion angle, the higher the evaporation rate. This is, among other reasons, due to the fact that a flat immersion angle increases turbulence inside the evaporating flask, hence accelerating the evaporation. However, with a flatter immersion angle the evaporating flask cannot be as deeply immersed in the heating bath medium compared with a steep immersion angle. This can be an issue especially working with smaller evaporating flasks. Generally speaking, a 40 degrees immersion angle leads to a maximum efficiency rate without restriction in handling or risking losing parts of the sample due to over spilling and bumping into the receiving flask.