Ammonium, nitrate, and total nitrogen determination in fly ash

Fly-ash is a by-product of the combustion of pulverized coal and is composed of small particles. Nowadays, air pollution control standards require a separation of flue gas before being released to the atmosphere.The composition of the fly ash may vary considerabley, however, all fly ashed contain substantial amounts of silicon dioxide (SiO2) aluminium oxide (Al2O3) and calcium oxide (CaO). The fly ash in this study was provided from a pulp mill containing organic and inorganic (ammonium nitrate and ammonium sulfate) nitrogen compounds.

TKN determination in water and wastewater

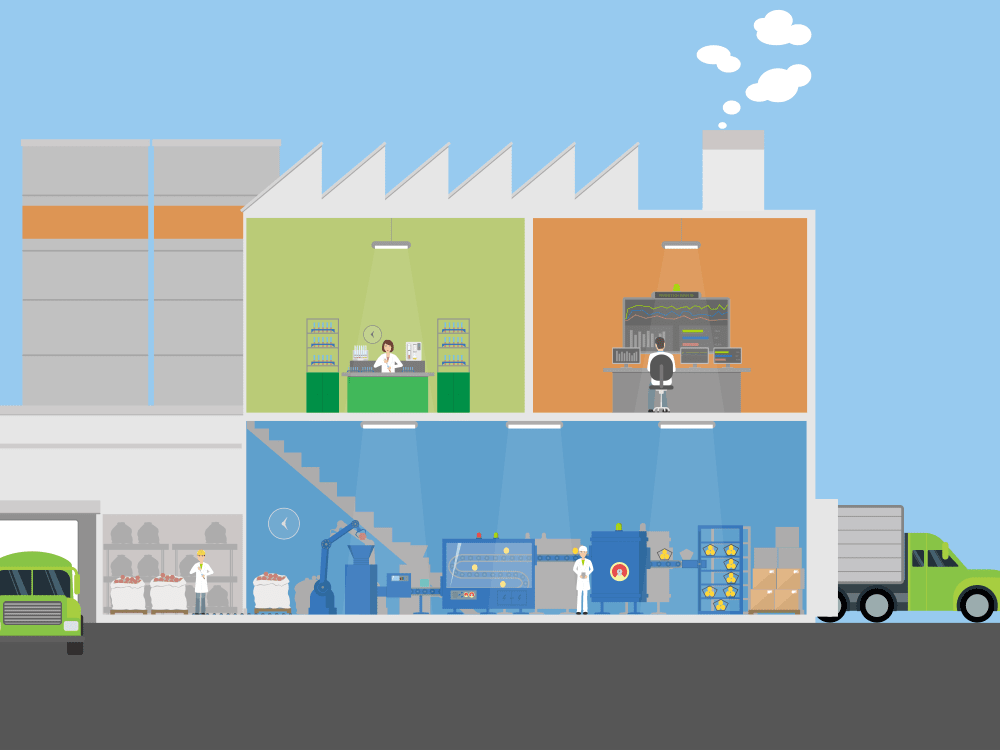

SpeedDigester K-439, Kjel Line and MultiDist: Steam distillation and Potentiometric determination of Total Kjeldahl Nitrogen (TKN) according to the Kjeldahl method in water and wastewater along with determination of Limit of Detection (LOD) and Limit of Quantification (LOQ).