Spray Drying of Oxyhemoglobin

Spray drying has been used to prepare Oxyhemoglobin (OxyHb) nanoparticles, which are useful in drug delivery applications. The process involves the formation of OxyHb nanoparticles by spray drying a solution containing OxyHb and a biodegradable polymer such as poly(lactide-co-glycolide) (PLGA). Spray drying leads to the formation of a dry powder, which can be easily stored and transported.

OxyHb nanoparticles are being investigated for their use in targeted drug delivery systems, as they can be used to deliver drugs to specific tissues in the body. They can also be used to enhance the therapeutic efficacy of drugs, reduce their side effects and improve their bioavailability.

OxyHb nanoparticles have also been studied for their use in oxygen carriers for blood substitutes. Spray drying has been used to prepare OxyHb nanoparticles coated with a biocompatible polymer, which can be used as oxygen carriers in the treatment of anemia and other blood-related disorders.

Please see the application note No. 596 for starting parameters and some results.

Spray Drying of Passion flower

Passion flower (Passiflora incarnata) is a plant known for its sedative and anxiolytic properties, making it useful in the treatment of anxiety and sleep disorders. Spray drying has been used to produce passion flower extract powders, which can be used to make supplements, herbal remedies, and functional foods.

The spray drying process involves atomizing a solution or suspension of passion flower extract into a hot gas stream, which rapidly evaporates the solvent, leaving behind a dry powder containing the passion flower extract.

Spray-dried passion flower extract powders have been shown to have improved stability, longer shelf life, and enhanced bioavailability compared to traditional liquid extracts. They can be used in a range of applications, including the development of dietary supplements, herbal remedies, and functional foods.

Overall, spray drying of passion flower extract offers numerous benefits and has a wide range of potential applications in the herbal and dietary supplement industries. Its versatility and adaptability make it a valuable tool for the development of new and innovative products with improved properties and health benefits.

Please see the application note No. 601 for starting parameters and some results.

Spray Drying of Oxaprozin

Oxaprozin is a nonsteroidal anti-inflammatory drug (NSAID) used to relieve inflammation, swelling, and stiffness in the body. Spray drying is a technique that has been used to formulate oxaprozin into various forms such as powders, capsules, and tablets. The process involves atomizing a liquid formulation into small droplets, which are then rapidly dried to form a fine powder. This results in an increase in surface area, which enhances dissolution and bioavailability of the drug.

Spray-dried oxaprozin has been used for various purposes such as improving drug stability, solubility, and oral bioavailability. The technique has also been used to formulate sustained-release formulations of oxaprozin, which can provide controlled drug delivery over an extended period. In addition, spray-dried oxaprozin has been incorporated into polymeric nanoparticles, which can improve drug targeting and reduce toxicity.

Overall, the spray drying of oxaprozin has numerous potential applications in the pharmaceutical industry, including drug formulation, drug delivery, and improved therapeutic efficacy.

Please see the application note No. 595 for starting parameters and some results.

Spray Drying of Peach oil

Peach oil is a natural oil extracted from the kernels of peaches and has various applications in the cosmetic and food industries. Spray drying is a common method used to convert peach oil into a dry powder or particles for improved handling and storage.

The spray drying process involves atomizing a peach oil solution or suspension into a hot gas stream, which rapidly evaporates the solvent, leaving behind a dry powder or particles containing peach oil. The size and shape of the particles can be controlled by adjusting the spray drying conditions, such as the feed rate, drying temperature, and gas flow rate.

Spray-dried peach oil particles have numerous applications in the cosmetic industry. The dry powder can be used in formulations for skin and hair care products, such as lotions, creams, shampoos, and conditioners. In the food industry, spray-dried peach oil particles can be added to dry mixes for baked goods, desserts, and snacks to enhance their flavor and nutritional value.

Overall, spray drying of peach oil is a versatile and efficient process that offers various benefits and has a wide range of applications. It provides a stable, free-flowing powder or particles that are easier to handle and store, making it a valuable tool for the development of new and innovative products in the cosmetic and food industries.

Please see the application note No. 602 for starting parameters and some results.

Spray Drying of Plant Extracts for Liquor

Spray drying of plant extracts for liquor is a popular technique used in the food and beverage industry to improve the shelf life of natural extracts and enhance their functionality. The process involves atomizing a solution or suspension of plant extracts into a hot gas stream, where the solvent evaporates, leaving behind a fine powder.

The plant extracts used for liquor are typically rich in antioxidants, flavor compounds, and other bioactive ingredients that can provide health benefits and improve the sensory properties of beverages. Some common plant extracts used in liquor production include herbs, spices, fruits, and vegetables. Spray drying allows manufacturers to preserve the potency and flavor of these extracts while improving their solubility and stability.

Spray-dried plant extracts are used in the production of various alcoholic beverages, including beer, wine, and spirits. They are also used in non-alcoholic beverages such as soft drinks and functional beverages. Additionally, they are used as ingredients in food products like confectionery, bakery, and snack foods.

Please see the application note No. 611 for starting parameters and some results.

Spray Drying of Probiotic Milk

Spray drying is a commonly used technique in the food industry to produce dry powders from liquid solutions or suspensions. In recent years, spray drying has been utilized in the production of probiotic milk powders, which offer numerous benefits and advantages over conventional methods of probiotic milk production.

Spray drying of probiotic milk allows for the production of powders with improved stability, longer shelf life, and enhanced bioavailability. The process involves atomizing the milk and probiotic culture into a hot gas stream, which rapidly evaporates the water, leaving behind a dry powder that contains the probiotic microorganisms.

Applications of spray-dried probiotic milk powders include the development of functional food products, such as yogurt, cheese, and infant formula, which can provide a range of health benefits. Probiotic milk powders can also be used in the development of dietary supplements and nutraceuticals.

Overall, spray drying of probiotic milk offers numerous benefits and has a wide range of potential applications in the food industry. Its versatility and adaptability make it a valuable tool for the development of new and innovative functional food products with improved properties and health benefits.

Please see the application note No. 629 for starting parameters and some results.

Spray Drying of Norfenefrine-HCl

Spray drying of Norfenefrine-HCl is a process that converts a liquid solution into a dry, powdered form. Norfenefrine-HCl is a sympathomimetic drug used in the treatment of hypotension (low blood pressure). It works by stimulating alpha-adrenergic receptors, leading to an increase in peripheral vascular resistance and blood pressure. Spray drying can be used to improve the solubility and bioavailability of the drug by reducing particle size and increasing surface area. The resulting powder is easy to handle, store, and transport, and can be formulated into various dosage forms such as tablets, capsules, or injectables.

Spray-dried Norfenefrine-HCl has several applications in the pharmaceutical industry, including the development of sustained-release dosage forms, nasal sprays, and inhalation formulations. It is also used in the preparation of parenteral solutions and for the treatment of shock, heart failure, and other circulatory disorders. Spray drying technology provides a cost-effective and efficient method for producing high-quality Norfenefrine-HCl powder with enhanced physicochemical properties for various pharmaceutical applications.

Please see the application note No. 588 for starting parameters, formulations and some results.

Spray Drying of Polyacrylic acid

Polyacrylic acid (PAA) is a synthetic polymer used in a wide range of industrial and biomedical applications, including drug delivery, wound dressings, and superabsorbent materials. Spray drying has been used to produce PAA particles in various forms, such as nanoparticles, microparticles, and aerogels.

The spray drying process involves atomizing a solution or suspension of PAA into a hot gas stream, which rapidly evaporates the solvent, leaving behind a dry powder containing PAA particles. The size, shape, and properties of the particles can be controlled by adjusting the spray drying conditions, such as the feed rate, drying temperature, and gas flow rate.

Applications of spray-dried PAA particles include drug delivery systems, wound dressings, and superabsorbent materials. The PAA particles can be functionalized with various drugs, biomolecules, or functional groups to enhance their properties and performance.

Overall, spray drying of PAA particles offers numerous benefits and has a wide range of potential applications in the industrial and biomedical fields. Its versatility and adaptability make it a valuable tool for the development of new and innovative materials with improved properties and performance.

Please see the application note No. 617 for starting parameters and some results.

Spray Drying of Pigment

Spray drying is a commonly used technique for the production of pigments in various industries. Pigments are used in a wide range of applications, including paints, inks, cosmetics, and plastics. Spray drying of pigments involves the production of fine powders by converting liquid pigments into solid particles using a spray dryer. The process involves atomizing the liquid pigment into small droplets that are rapidly dried in a hot gas stream, resulting in the formation of fine powder particles.

The advantages of spray drying for pigment production include improved dispersion and flow properties, reduced caking and agglomeration, and increased shelf life. The process also allows for precise control of particle size and morphology, which can affect the properties and performance of the final product.

Some examples of pigments produced using spray drying include titanium dioxide, iron oxide, and carbon black. These pigments are used in a wide range of applications, including automotive coatings, plastic colorants, and inkjet inks.

Please see the application note No. 610 for starting parameters and some results.

Spray Drying of Plasmid DNA

Spray drying of plasmid DNA is a method used to produce dry, stable and highly concentrated forms of the genetic material. This technique involves transforming plasmid DNA into a dried powder form by dispersing a liquid solution of the DNA into an inert gas stream and then rapidly drying it. The resulting powder can be easily stored, transported and reconstituted when needed.

One of the most promising applications of spray drying of plasmid DNA is in the field of gene therapy. Gene therapy aims to correct genetic disorders by delivering therapeutic genes to specific cells. Spray-dried plasmid DNA can be used to create inhalable dry powder formulations for the treatment of respiratory diseases. Additionally, this technique can also be used to produce dry powder formulations of plasmid DNA vaccines.

Another area of application is in the production of plasmid DNA for research purposes. Spray drying offers an efficient and scalable method to produce large quantities of high-quality DNA for use in molecular biology studies.

Overall, spray drying of plasmid DNA has significant potential in the field of gene therapy and research, providing a stable and easy-to-use form of genetic material for a range of applications.

Please see the application note No. 612 for starting parameters and some results.

Spray Drying of Polyacrylate

Polyacrylate is a polymer that has a wide range of applications in the industrial, agricultural, and biomedical fields. Spray drying has been utilized to produce polyacrylate particles with controlled size, shape, and properties.

The spray drying process involves atomizing a polyacrylate solution or suspension into a hot gas stream, which rapidly evaporates the solvent, leaving behind a dry powder or particles containing polyacrylate. The size and shape of the particles can be controlled by adjusting the spray drying conditions, such as the feed rate, drying temperature, and gas flow rate.

Polyacrylate particles produced by spray drying have been utilized in various industrial applications such as water treatment, coating, and adhesives. In the agricultural field, spray-dried polyacrylate particles have been used as soil conditioners to improve water retention and plant growth. In the biomedical field, spray-dried polyacrylate particles have been used for drug delivery and tissue engineering.

Overall, spray drying of polyacrylate particles is a versatile and efficient process that offers numerous benefits and has a wide range of potential applications. Its ability to produce particles with controlled size and properties makes it a valuable tool for the development of new and innovative materials.

Please see the application note No. 615 for starting parameters and some results.

Spray Drying of Poly-Caprolatone Nanospheres and Nanocapsules of Miglyol

Poly-caprolactone (PCL) is a biodegradable polymer that has been widely used in drug delivery applications. Spray drying has been employed to produce PCL nanospheres and nanocapsules of Miglyol, which can be used to encapsulate drugs and improve their delivery and bioavailability.

The spray drying process involves atomizing a solution or suspension of PCL and Miglyol into a hot gas stream, which rapidly evaporates the solvent, leaving behind a dry powder containing the PCL nanospheres or nanocapsules.

Applications of spray-dried PCL nanospheres and nanocapsules of Miglyol include the development of drug delivery systems with improved release profiles, increased stability, and enhanced bioavailability. These systems can be used for a wide range of therapeutic applications, including cancer therapy, gene therapy, and vaccine delivery.

Overall, spray drying of PCL nanospheres and nanocapsules of Miglyol offers numerous benefits and has a wide range of potential applications in the field of drug delivery. Its versatility and adaptability make it a valuable tool for the development of new and innovative drug delivery systems with improved properties and performance.

Please see the application note No. 618 for starting parameters and some results.

Spray Drying of Polyetherimid

Polyetherimide (PEI) is a high-performance thermoplastic material with a broad range of applications in various industries such as aerospace, automotive, and electronics. Spray drying is a technique that has been applied to the production of PEI powders, offering several advantages in terms of product quality, performance, and process efficiency.

Spray drying of PEI allows for the production of powders with controlled particle size and morphology, which can be tailored to specific applications. The resulting powders have high purity, low dust content, and improved solubility, making them suitable for a wide range of processing and manufacturing applications.

Applications of PEI powders produced by spray drying include the manufacture of coatings, films, and other high-performance materials. The process can also be used to produce PEI powders with enhanced mechanical properties, such as increased toughness, stiffness, and thermal resistance.

Overall, spray drying of PEI offers numerous benefits and has a wide range of potential applications in various industries, including engineering, manufacturing, and materials science. Its versatility and adaptability make it a valuable tool for the development of new and innovative products.

Please see the application note No. 619 for starting parameters and some results.

Spray Drying of Print colour

Spray drying is a technique that has been used in the printing industry to produce dry powdered pigments and dyes used in printing ink formulations. The spray drying process involves atomizing a liquid solution or suspension of the pigments or dyes into a hot gas stream, which rapidly evaporates the solvent, leaving behind a dry powder.

Spray drying of print color offers numerous advantages over conventional methods of pigment and dye production. It allows for the production of powders with controlled particle size and morphology, which can be tailored to specific applications. The resulting powders have improved dispersibility, color intensity, and printing properties, making them suitable for various printing applications.

Applications of spray-dried print color powders include the development of inks for inkjet and digital printing, as well as conventional printing methods such as flexography and offset printing. The powders can be used in a wide range of printing applications, including packaging, labels, textiles, and ceramics.

Overall, spray drying of print color offers numerous benefits and has a wide range of potential applications in the printing industry. Its versatility and adaptability make it a valuable tool for the development of new and innovative printing inks with improved properties and performance.

Please see the application note No. 628 for starting parameters and some results.

Spray Drying of Paracetamol

Spray drying is a process used to transform a liquid into a dry powder form. Paracetamol (acetaminophen) is a widely used analgesic and antipyretic drug used to treat pain and fever. Spray drying of paracetamol has been studied as a means of improving the drug's solubility, bioavailability, and stability.

The process of spray drying involves atomizing a solution of paracetamol into a stream of hot gas, which evaporates the solvent and leaves behind a fine powder. The resulting paracetamol powder is highly dispersible and can be easily formulated into various dosage forms such as tablets, capsules, or oral suspensions.

Spray drying of paracetamol has been used in a variety of applications, including the production of fast-dissolving tablets, orodispersible films, and orally disintegrating tablets. The process has also been used to improve the stability of paracetamol and to reduce the drug's gastrointestinal side effects.

In summary, spray drying of paracetamol is a promising technology that has the potential to improve the efficacy, safety, and convenience of this widely used analgesic and antipyretic drug. Its applications extend to many different areas of drug delivery, including fast-dissolving dosage forms and orally disintegrating tablets.

Please see the application note for starting parameters, formulations and some results.

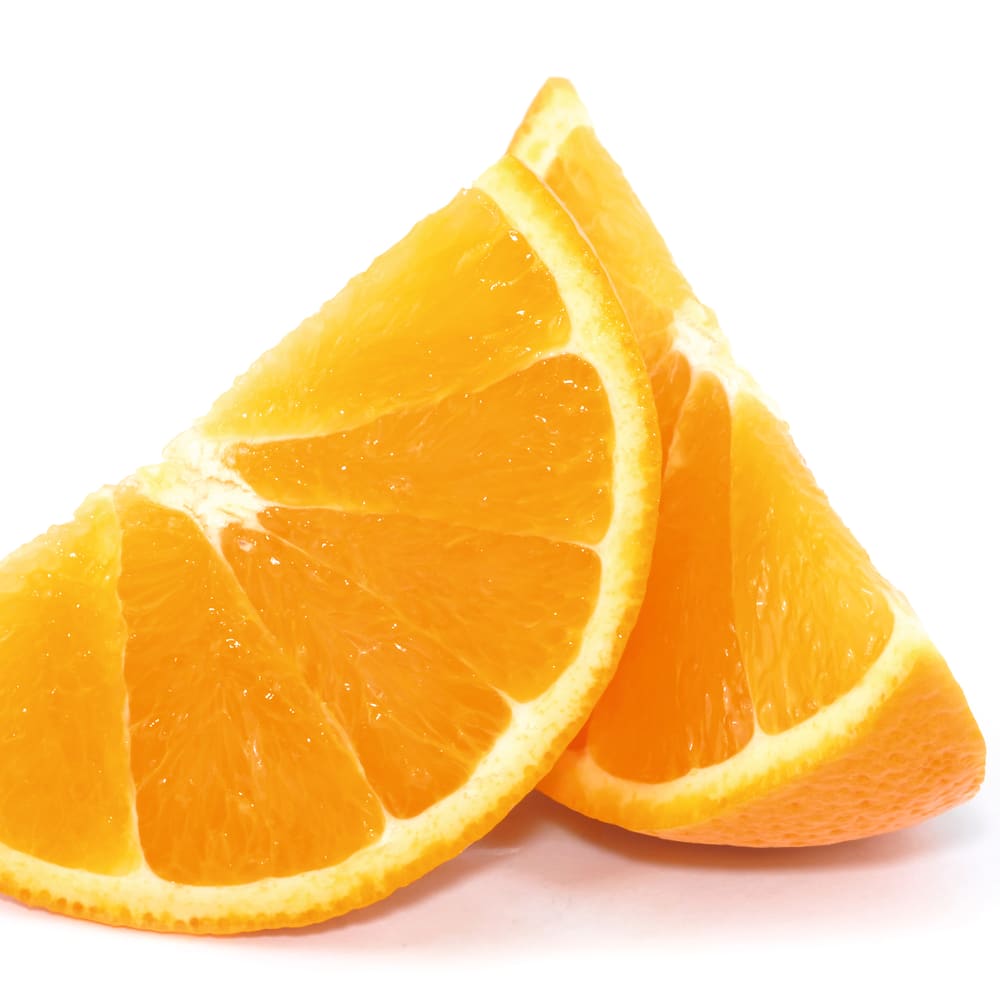

Spray Drying of Orange concentrate

Spray drying of orange concentrate involves the conversion of liquid orange juice concentrate into a dry powder through a process that involves atomizing the concentrate into small droplets which are then dried by hot air. The resulting powder has good solubility and is easy to transport and store, making it a popular ingredient in the food and beverage industry.

The powder is commonly used as an additive in various food products such as fruit juices, ice creams, yogurts, and baked goods. The use of spray-dried orange concentrate in these products enhances their flavor and aroma while also improving their texture and stability.

The powder is also used in the production of nutritional supplements due to its high content of vitamins and antioxidants. It can be added to powdered drink mixes, capsules, and tablets to boost their nutritional value.

Furthermore, spray-dried orange concentrate can be used as a natural food colorant due to its bright orange color. It can be added to various food products such as confectionery, jams, and jellies to enhance their visual appeal.

Please see the application note No. 592 for starting parameters and some results.

Spray Drying of Porcine Lactate Dehydrogenase

Porcine lactate dehydrogenase (pLDH) is an important enzyme used in various biotechnological and pharmaceutical applications, including diagnostics and drug development. Spray drying has emerged as an effective technique for producing powdered forms of pLDH.

Spray drying of pLDH allows for the production of powders with controlled particle size and morphology, which can be tailored to specific applications. The resulting powders have improved stability, making them suitable for long-term storage and shipping. Additionally, the process preserves the enzymatic activity of pLDH, making it useful for various applications in biotechnology and pharmaceutical industries.

Applications of pLDH powders produced by spray drying include the development of diagnostic kits for detecting diseases, production of biosensors, and drug discovery. The process can also be used to produce pLDH powders with enhanced properties, such as increased stability, shelf life, and solubility.

Overall, spray drying of pLDH offers numerous benefits and has a wide range of potential applications in various industries, including healthcare and biotechnology. Its versatility and adaptability make it a valuable tool for the development of new and innovative products.

Please see the application note No. 625 for starting parameters and some results.

Spray Drying of Prednisolone Acetate

Prednisolone acetate is a synthetic corticosteroid used in various pharmaceutical formulations, particularly in ophthalmic applications. Spray drying has been utilized as a technique to produce prednisolone acetate powders with improved properties.

Spray drying of prednisolone acetate allows for the production of powders with controlled particle size and morphology, which can be tailored to specific applications. The resulting powders have improved solubility, dissolution rate, and bioavailability, making them suitable for various pharmaceutical applications.

Applications of prednisolone acetate powders produced by spray drying include the development of ophthalmic formulations, such as eye drops, for the treatment of various ocular conditions, including inflammation and allergic reactions. The powders can also be used in the development of inhalation formulations for the treatment of respiratory conditions.

Overall, spray drying of prednisolone acetate offers numerous benefits and has a wide range of potential applications in the pharmaceutical industry. Its versatility and adaptability make it a valuable tool for the development of new and innovative formulations with improved properties and efficacy.

Please see the application note No. 627 for starting parameters and some results.

Spray Drying of Polyacrylamide

Polyacrylamide (PAM) is a synthetic polymer widely used in various industrial and environmental applications, including water treatment, oil recovery, and papermaking. Spray drying has been used to produce PAM particles in various forms, such as nanoparticles, microparticles, and fibers.

The spray drying process involves atomizing a solution or suspension of PAM into a hot gas stream, which rapidly evaporates the solvent, leaving behind a dry powder or fibers containing PAM particles. The size, shape, and properties of the particles can be controlled by adjusting the spray drying conditions, such as the feed rate, drying temperature, and gas flow rate.

Applications of spray-dried PAM particles include water treatment, oil recovery, and papermaking. The PAM particles can be functionalized with various functional groups to enhance their properties and performance, such as improving the efficiency of flocculation, reducing the viscosity of drilling fluids, and enhancing the strength of paper.

Overall, spray drying of PAM particles offers numerous benefits and has a wide range of potential applications in the industrial and environmental fields. Its versatility and adaptability make it a valuable tool for the development of new and innovative materials with improved properties and performance.

Please see the application note No. 614 for starting parameters and some results.

Spray Drying of Progesterone

Spray drying is a widely used technique in the pharmaceutical industry for the production of dry powders from liquid formulations. One example of its application is in the production of progesterone powder, a hormone used in the treatment of infertility, premenstrual syndrome, and other conditions.

Spray drying of progesterone offers several advantages over other drying methods, including improved bioavailability, increased stability, and better control over particle size and morphology. The resulting powder is also easier to handle and store, making it a more practical and convenient form for pharmaceutical use.

The application of spray drying in progesterone production has been extensively studied in recent years, with researchers investigating different formulations and process parameters to optimize product properties. These studies have shown promising results, suggesting that spray drying may be a useful tool in the development of more effective and efficient progesterone products.

Overall, spray drying of progesterone has potential applications in the development of new drugs and the improvement of existing ones. Its versatility and adaptability make it a valuable tool in the pharmaceutical industry, offering benefits in terms of product quality, performance, and process efficiency.

Please find starting parameters and some Results in this Application Note No. 630.