BUCHI NIR-Online® launches a new sensor for essential process control

The X-Sential™ was developed and designed as a cost-effective, fit-for-purpose process sensor. By using diode array technology, the sensor spectrometer does not contain any moving parts, making it extremely fast and robust. The industry-proven design stands up to rough conditions like vibration, extreme temperatures, wind, dust, and humidity. The new system is certified to IP69/X9K for ingress protection and delivers state-of-the-art monitoring for basic parameters such as moisture, fat, and protein in manufacturing processes.

Like all BUCHI NIR-Online® process sensors, the newest member of the proven NIR product portfolio features the same superior robustness, combined Swiss and German quality, and ease of use. “No expert knowledge is needed to operate the X-Sential™ with its unique AutoCal functionality,” says Michael Eckert, Product Manager Technology, Development & Support for NIR-Online. “The X-Sential™ can be easily implemented into existing quality control routines. Consequently, there’s no need to invest in commercial calibration databases or extensive inhouse calibration development. With our wide range of process adapters, the sensor can be perfectly integrated into our customers’ production lines.”

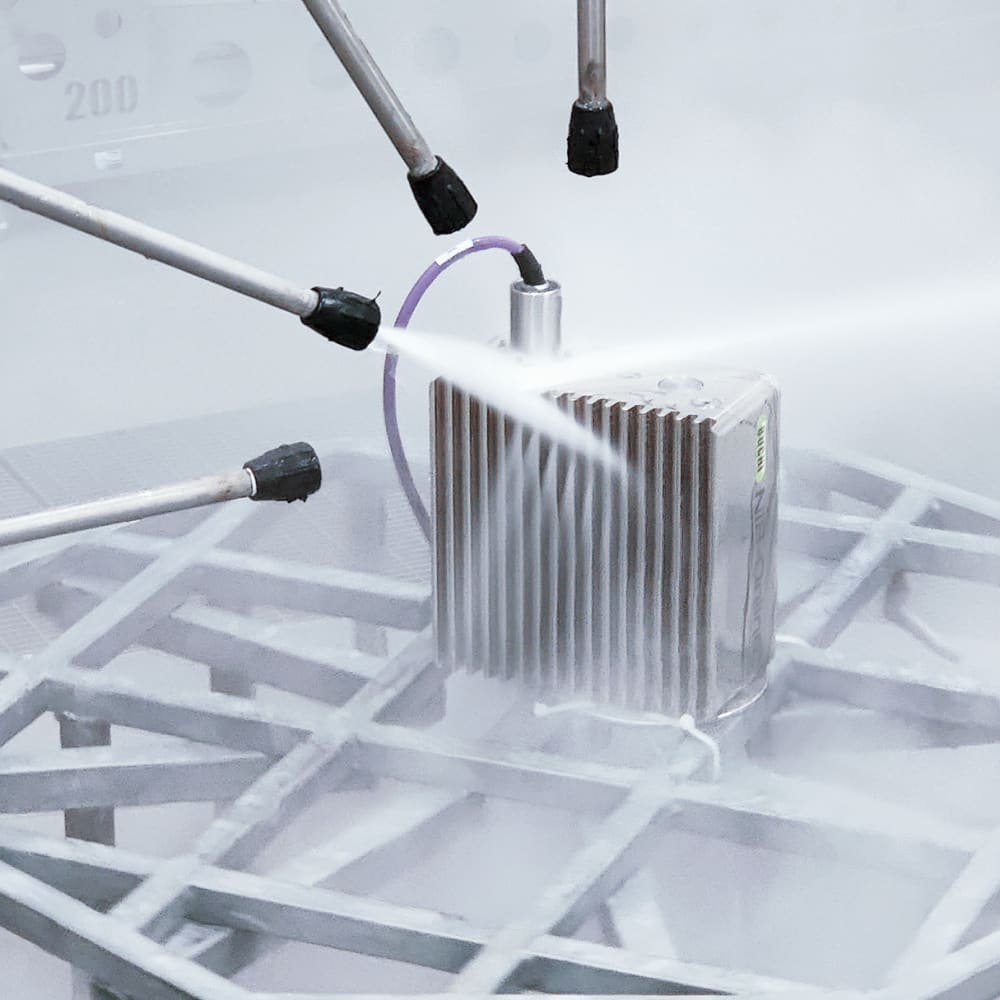

The compact, robust instrument is the result of extensive process expertise. The X-Sential™ sensor’s solid aluminum, nickel-coated housing provides a dust and water jet-protected sensor enclosure (IP69/X9K). Equipped with a temperature-stabilized spectrometer, it easily handles a wide range of ambient and product temperatures. “With the X-Sential™, you get a turnkey solution for fast, fluctuating, or discontinuous product streams. Furthermore, it can be easily integrated into process control systems,” emphasizes Eckert.

Because of its attractive price point, the average payback period is less than one year. For customers, whose applications do not require a premium spectrometer, the X-Sential™ sensor’s fit-for-purpose design delivers the best and most cost-effective choice. Basic quality parameters for raw materials and end products can be analyzed in large quantities and allow for real-time process corrections. This minimizes out-of-spec production and rework.