Applications

Results76

Determination of oil contents in seed samples

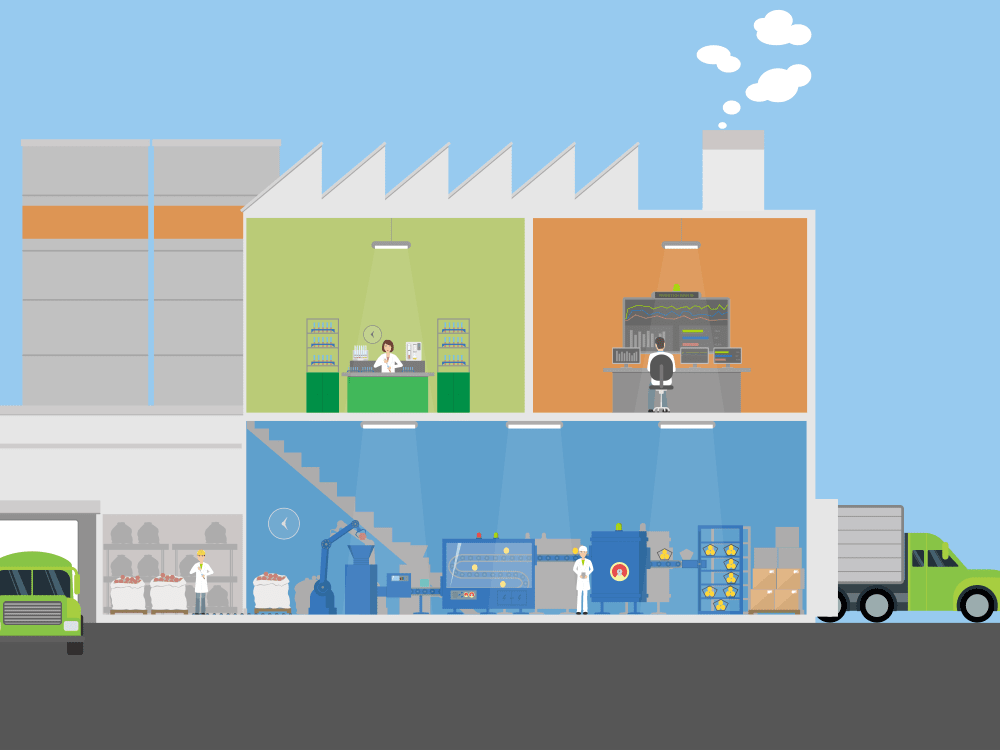

SpeedExtractor E-916, Multivapor, Hydrolysis Unit E-416, Extraction Unit E-816 SOX: Comparison of different extraction methods: Pressurized Solvent Extraction (PSE) using SpeedExtractor E-916 versus Weibull Stoldt method using Hydrolysis Unit E-416 and Extraction Unit E-816 SOX