Spray drying cemented tungsten carbide

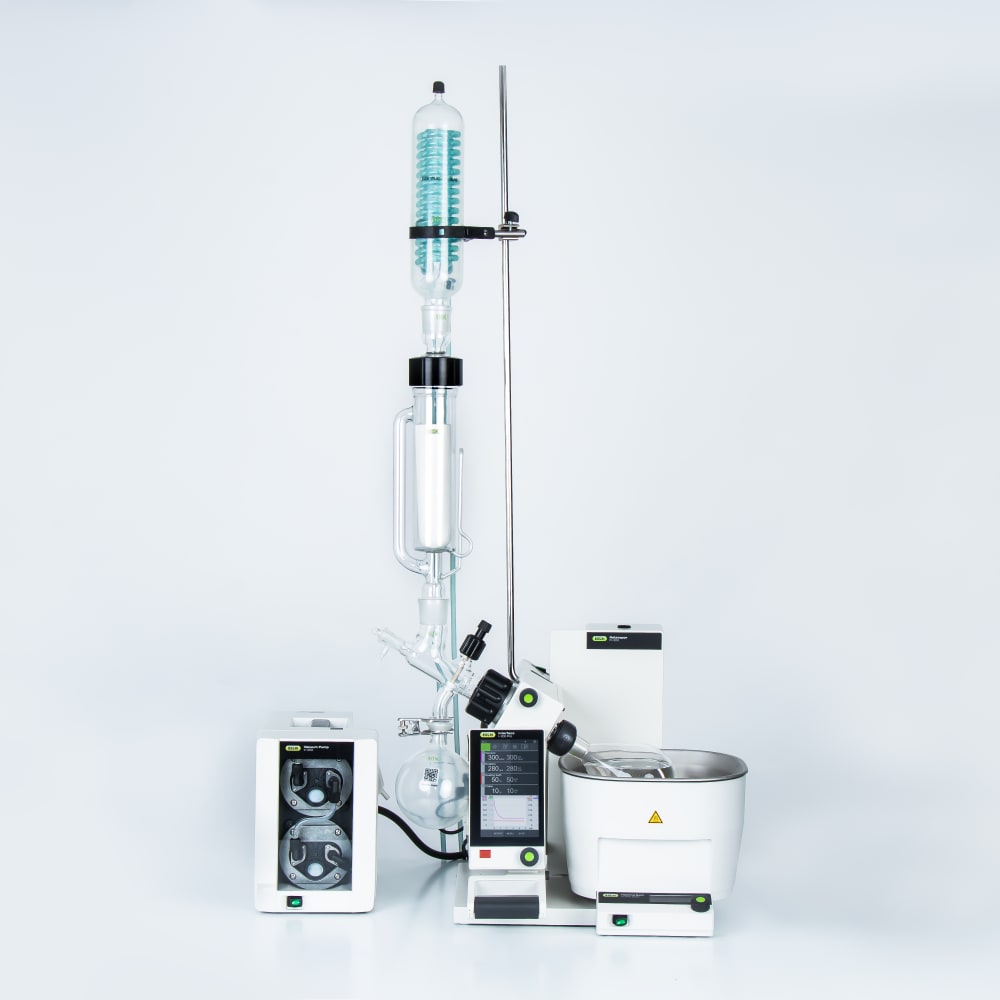

Cemented carbide is a hard material and famous for its good fracture toughness as well as extraordinary wear resistance. Major components of cemented carbide are tungsten carbide (WC) as a metal carbide and cobalt (Co) as a soft binder. It shows unique characteristics, such as high strength at elevated temperature, mechanical and chemical resistance. These properties render carbide tools appropriate for cutting, drilling, mining and machining. Of course, various kinds of other material carbides (titanium carbide, tantalum carbide, chrome carbide etc.) could be added.The conventional manufacturing process of cemented carbide includes wet milling of raw materials, spray drying, pressing, debinding and presintering, sintering, and finishing.In this application, we will highlight the important spray drying step to obtain WC/Co dried powder using the BUCHI Mini Spray Dryer B-290.

Cosmetics Lab Magazine Vol 3

In "COSMETICS LAB" Issue 3, find everything you need to know about the making of make-up. Improve your formulation proficiency by gaining insightful information on microencapsulation and spray drying. Plus read cosmetics formulation tips, recipes, quizzes, horscopes and an exlcusive interview with a microencapsulation expert.

Cosmetics Lab Magazine Vol 2

In "COSMETICS LAB" Issue 2, gain useful information on how to turn natural raw material into active compounds. Benefit from useful information on techniques used in all steps of cosmetics development. Learn how to extract and screen for active ingredients and how to use chromatography to purify raw material. Plus fun facts, horoscopes, quizzes and an exclusive interview on the topic of fighting misinformation in the cosmetics industry.