Quality in your hands

With our easy-to-use, high-quality laboratory and in-process solutions, we want to contribute to the health, safety and well-being of humans and the environment. Our specialists around the world actively support our customers in finding a perfect solution for their application.

Solutions Overview

Highlights

Industries

Pharma and Chemical

BUCHI offers a wide array of solutions for Pharma and Chemical R&D, with a focus on the synthesis work-up, natural products extraction, and formulation solutions.

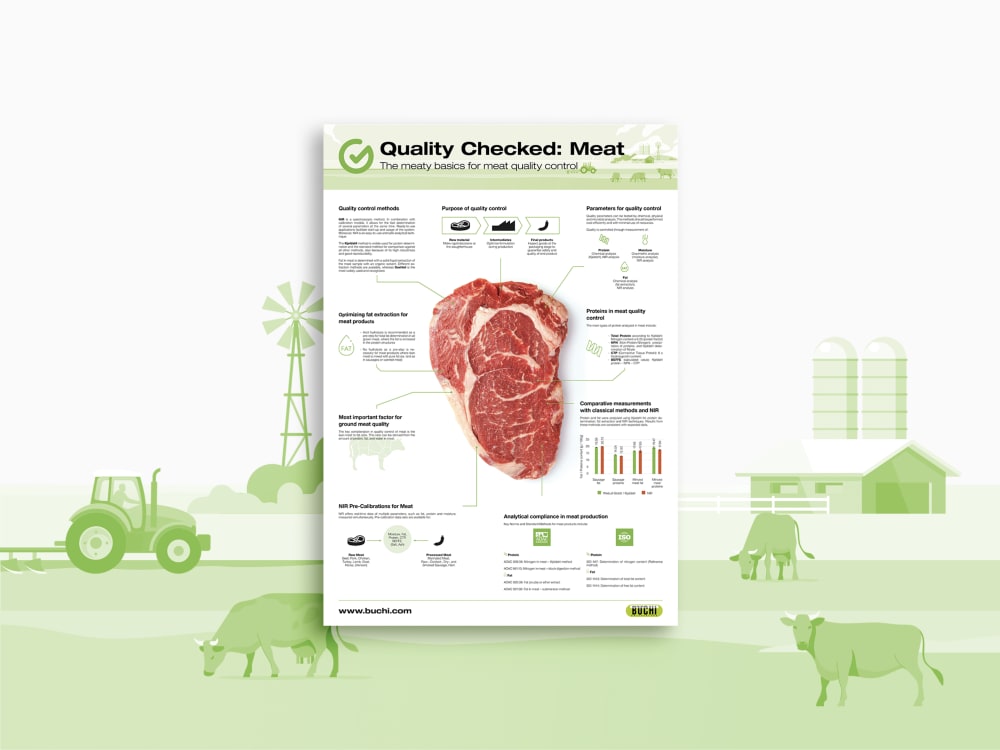

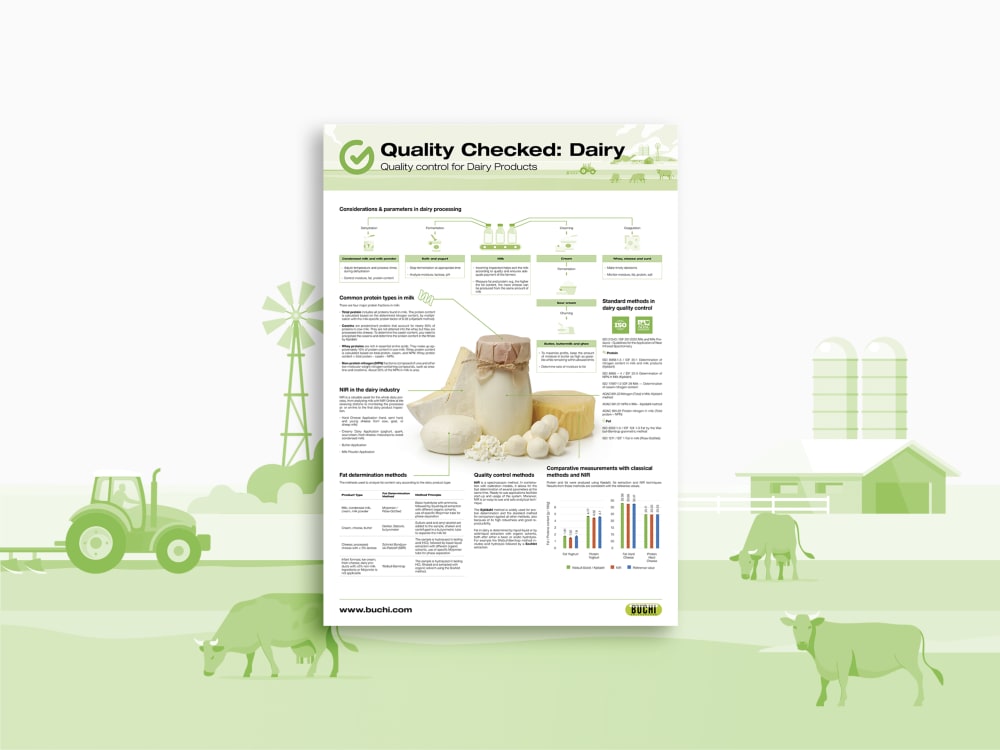

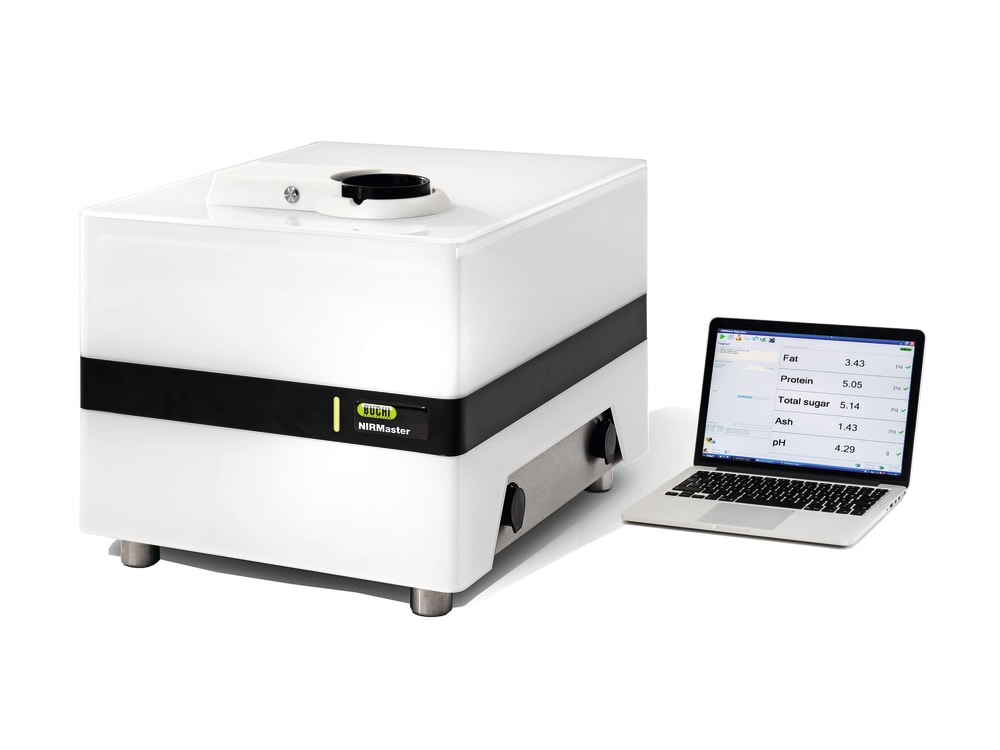

Food and Feed

Our Food, Beverage & Feed solutions focus on the determination of proximates such as protein, fat and many other parameters in the quality control laboratory as well as online in production.

Environmental

Our environmental solutions accelerate and automate the workup and analysis of many samples such as soil or air.

Rotavapor® R-80 System: Evaporation on the smallest footprint

2024 Apr. 11

April 2024, Flawil, Switzerland - BÜCHI Labortechnik AG, a leading provider of laboratory equipment, has added the Rotavapor® R-80 System to its portfolio. This entry-level instrument offers BUCHI quality at an affordable price and ensures the efficient...

BUCHI Unveils Branding for the Digital Age

2023 Nov. 14

We are excited to announce our refreshed branding, tailored to meet the demands of today's digital landscape while staying true to our core values of quality and innovation.

ILMAC Basel

2023 Sep. 4

Visit us from 26. - 28. September at ILMAC in Basel. We are at stand E173 and we are looking forward to see you!

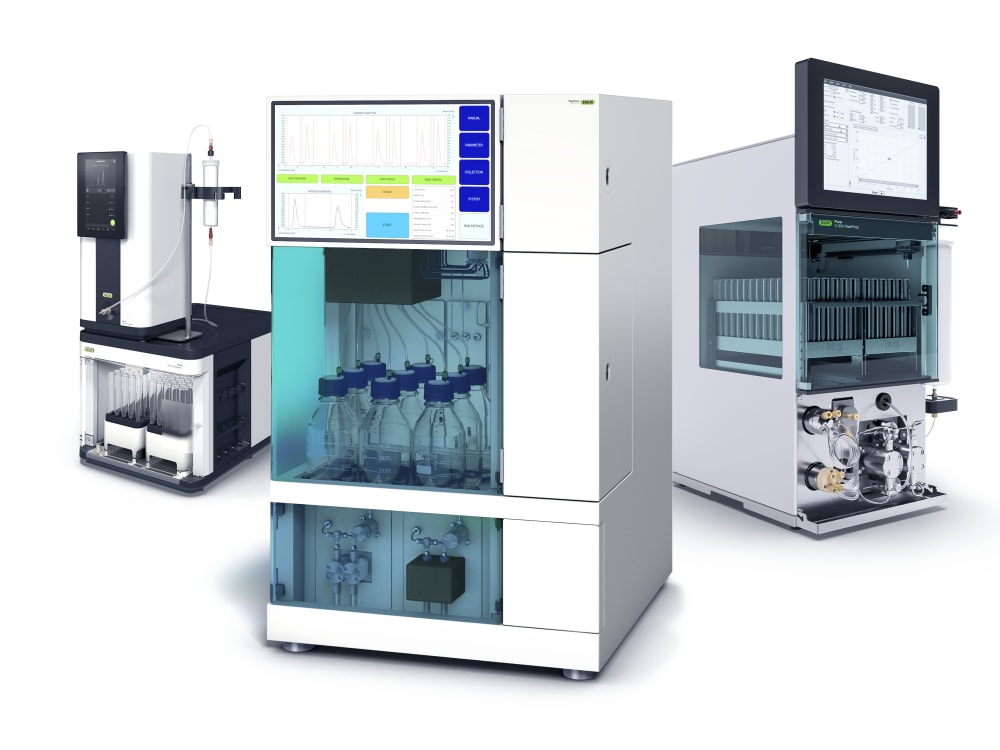

Pure Essential Chromatography System: First steps to fast separations

2023 Jun. 6

June 2023, Flawil, Switzerland - BÜCHI Labortechnik AG, a leading provider of laboratory equipment, has added the Pure Essential Chromatography system to its portfolio. This instrument serves as the ideal introduction to automated flash chromatography....

Sepiatec SFC Systems - The Green Standard for Fast Compound Isolation

2023 Jan. 17

January 2023, Flawil, Switzerland - BÜCHI Labortechnik AG, a leading provider of laboratory equipment, has added Sepiatec SFC, its first Supercritical Fluid Chromatography (SFC) systems, to its preparative chromatography portfolio. Thanks to smart system...

BUCHI Ibérica to serve Spain and Portugal

2022 Dec. 5

As of January 2023, Barcelona-based BUCHI Ibérica will take over the Portuguese market. The entire Iberian Peninsula will be handled exclusively by the BUCHI Group. An important milestone in the development of the Iberian market organization, which was...

SFC Pioneer Sepiatec acquired by BUCHI

2022 Aug. 31

Sepiatec, an innovative pioneer in Supercritical Fluid Chromatography Systems, headquartered in Berlin, has been acquired by Swiss lab equipment manufacturer BÜCHI Labortechnik AG.

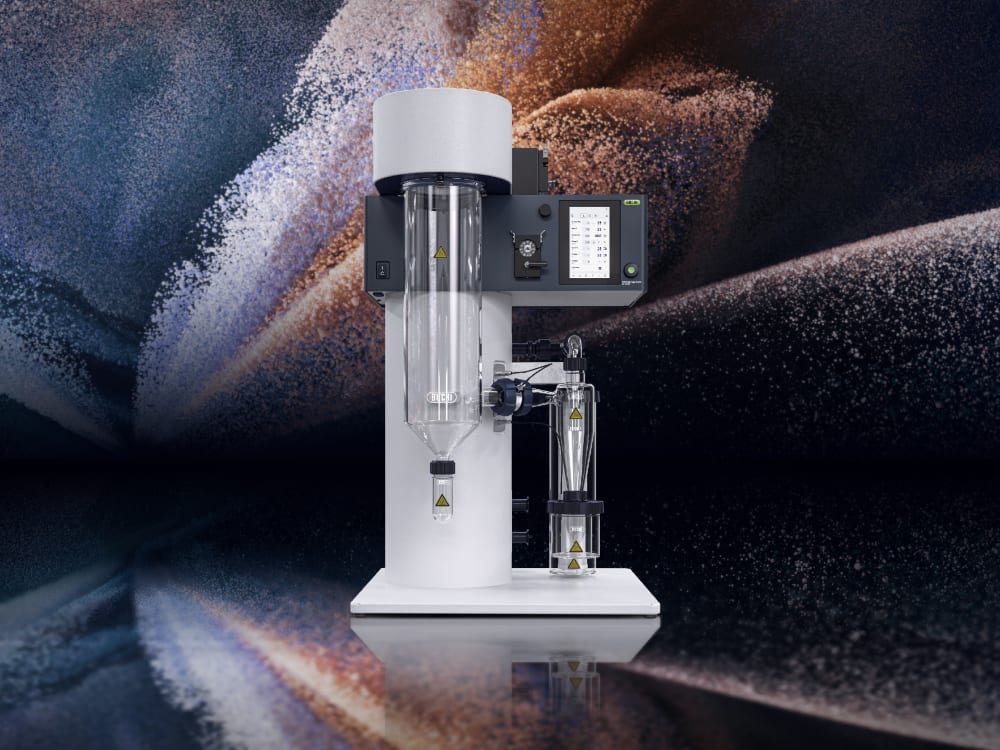

Automation and innovative design of BUCHI’s new Spray Dryer markedly improve spray drying performance

2022 Jun. 27

June 2022, Flawil, Switzerland - BUCHI Labortechnik, the global market leader in spray drying equipment for the last 40 years, has launched the Mini Spray Dryer S-300, a new generation of spray drying systems. The latest instrument combines novel automation...

BUCHI wins Swiss Export Award 2022

2022 Apr. 7

Today at the Swiss International Trade Forum at KKL Lucerne, Switzerland Global Enterprise (S-GE) presented this year’s Export Award to BÜCHI Labortechnik AG. The company impressed the jury with its international go-to-market strategy and beat Altoo...

Swiss Export Award 2022: BUCHI in the finals

2022 Mar. 17

Flawil, March 2022. The Export Award conferred annually by Switzerland Global Enterprise (S-GE) honors companies with international operations that show impressive results from their expansion strategy, the clarity of their internationalization concept,...

BUCHI opens Taiwan branch

2022 Jan. 3

Flawil/Taipei, 01.03.2022. With the establishment of a market organization in Taipei, BÜCHI Labortechnik AG is further expanding its global market presence.

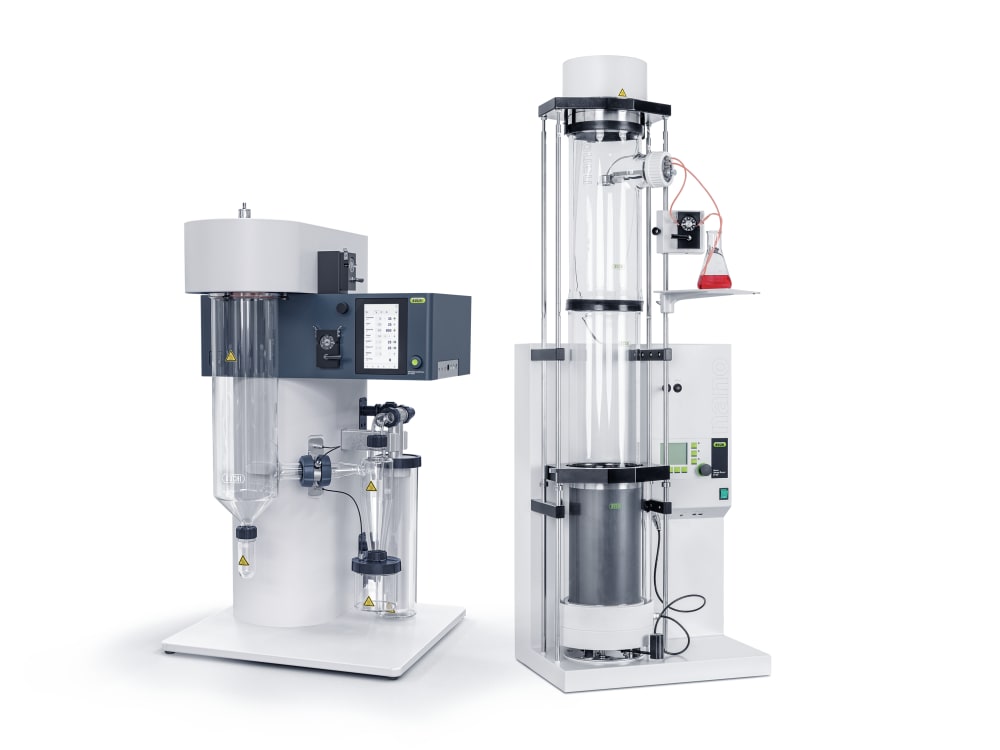

BUCHI’s new steam distillation units offer tailor-made solutions

2021 Jul. 22

July. 2021, Flawil, Switzerland - BÜCHI Labortechnik AG has launched two new product lines for steam distillation with innovative, modular features that provide the highest flexibility in analyte determination.

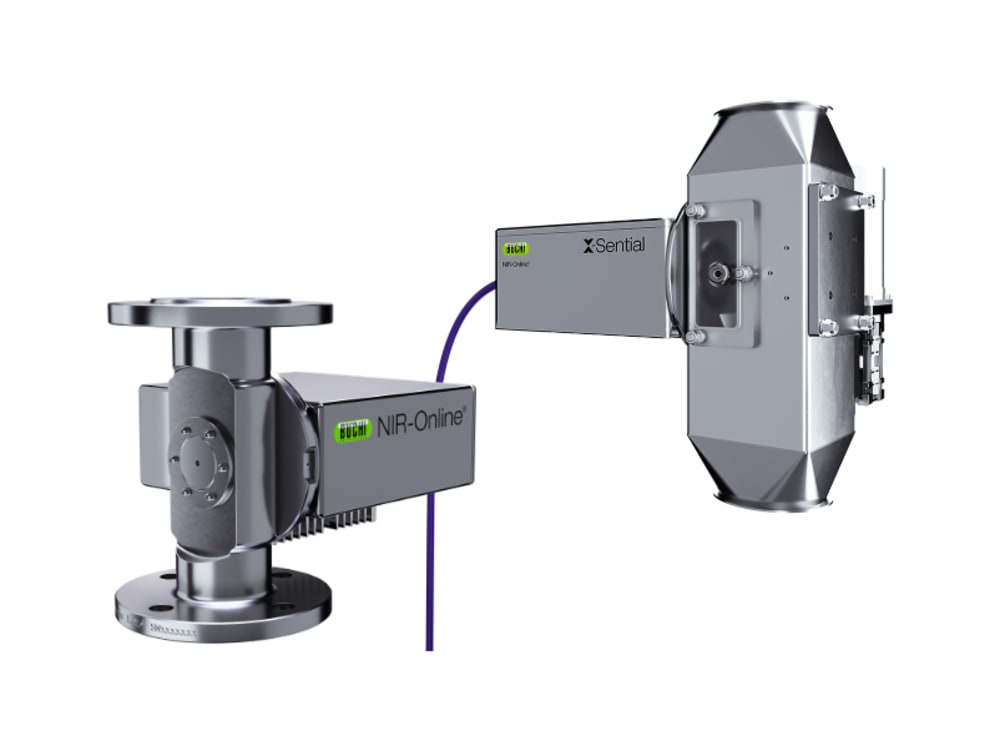

BUCHI NIR-Online® launches a new sensor for essential process control

2021 Jul. 12

Flawil, Switzerland, July 12, 2021 – With the launch of the NIR-Online X-Sential™, BÜCHI Labortechnik AG introduces a new process sensor that takes advantage of more than 15 years of in-the-field experience with process NIR technology and applicati

BUCHI expands direct distribution and support in Spain

2021 Jan. 10

BUCHI expands direct distribution and support by establishing BUCHI Ibérica S.L.