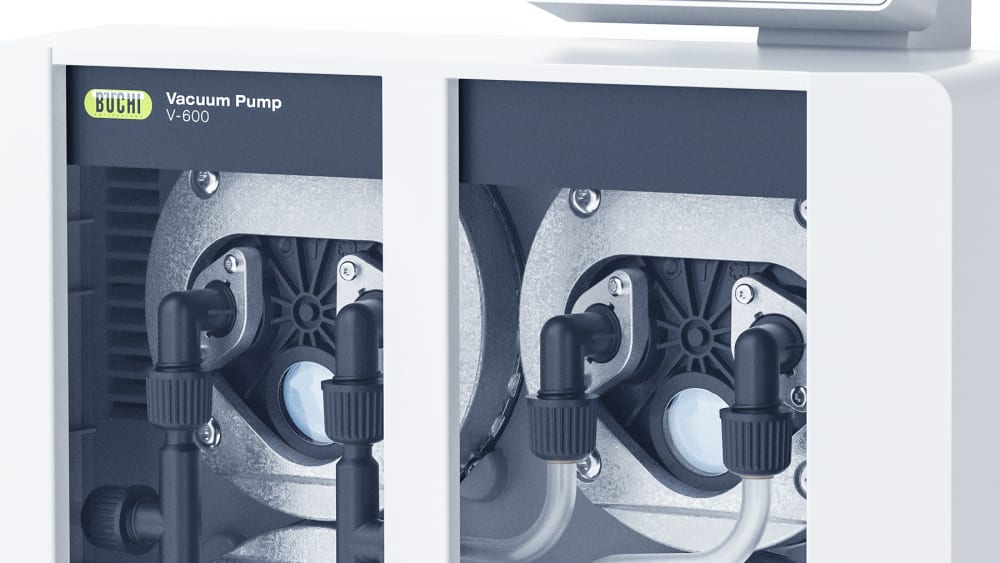

Vacuum Pump V-300 / V-600

Reliable pressure control for consistent distillations

The Vacuum Pump V-300 / V-600 is an essential system component for reliable pressure control for consistent distillations. Benefit from quiet, eco-friendly operations and the ability to distill solvents of any volume and with any boiling point.

Features

When connected to the interface, the speed control mode of the Vacuum Pump ensures pressure levels are held uniformly. This not only minimizes the risk of bumping, it also reduces noise emission significantly and extends the lifetime of the pump.

Thanks to speed-control, the pump operates smoothly to maintain the set vacuum. This results in very low noise emission (as low as 32 dB) and a more comfortable working environment.

You can directly see any condensed solvents or particles through a transparent inspection window to facilitate the maintenance of your vacuum pump.

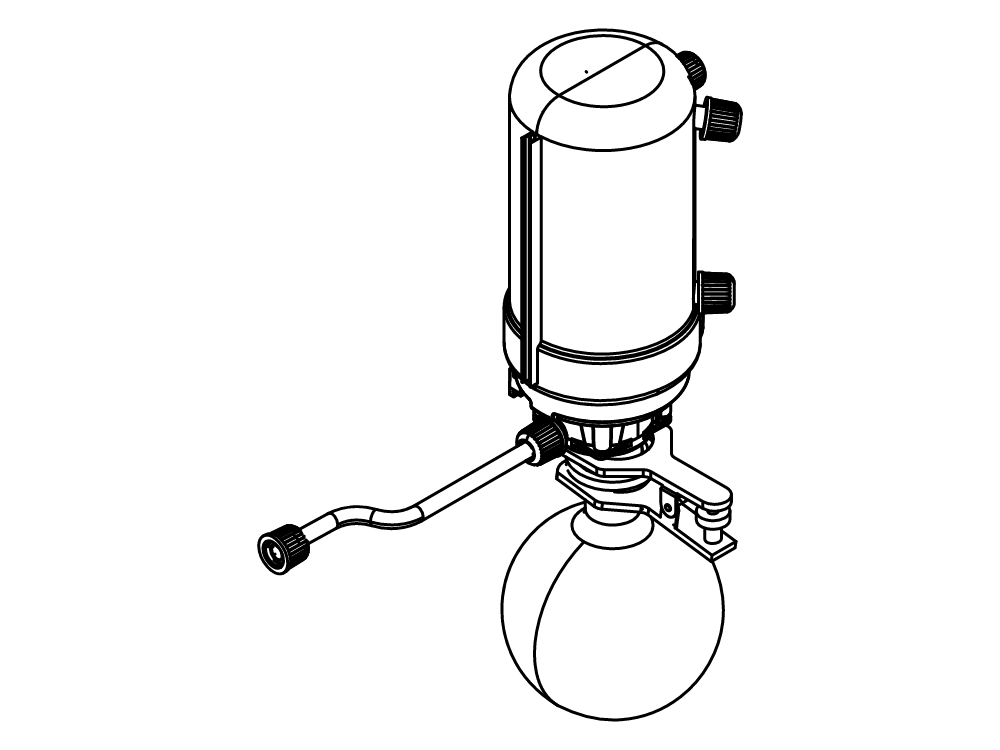

A secondary condenser prevents solvent that is sucked into the vacuum pump from being released into the environment. This condenser is beneficial for cases where low boiling solvents are used or when pressure values are set too aggressively.

You can directly see any condensed solvents or particles through a transparent inspection window to facilitate the maintenance of your vacuum pump.

When not connected to the interface, the pump automatically switches to power savings mode after a given time interval has passed. This leads to substantial energy and cost savings.

Compare the Vacuum Pump V-300 / V-600

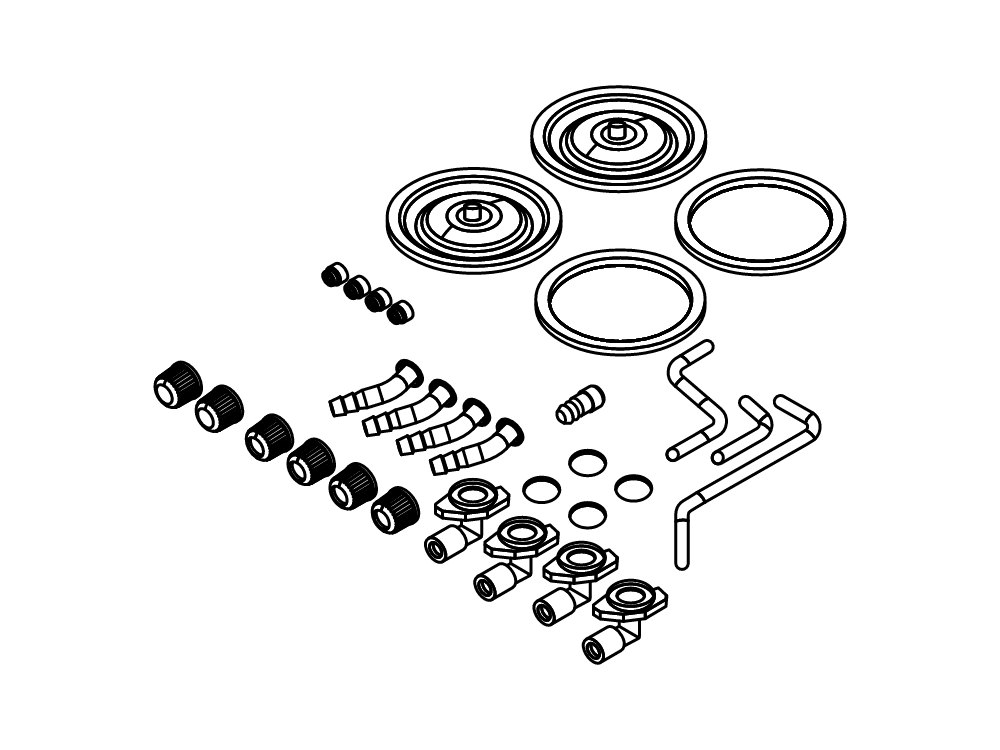

Related Parts & Accessories

Downloads

- Operation Manual Vacuum Pump V-600 en(pdf)

- Operation Manual Vacuum Pump V-300 en(pdf)

- Technical Data Sheet Vacuum Pump V-300 / V-600(pdf)

- Product Brochure Vacuum Pump V-600 en(pdf)

- Solution Brochure Environmental Analysis en(pdf)

- Product Brochure Vacuum Pump V-300 en(pdf)

Related Instruments

Applications

Benefit from decades of expert knowledge

Chemical

For every day’s application in QC and R&D laboratories: Concentration, Reflux reaction, Re-crystallization.

Environmental Analysis

Required for sample preparation in order to monitor the environmental pollution: Soxhlet extraction, Concentration.

Academia / Education

For a wide range of applications in academic education: Full range of evaporation applications.

Pharmaceutical

For various applications in QC as well as for laboratory scale formulations in R&D departments: Distillation, Concentration, Drying.

Food / Beverage

Used for QC in the food, beverage and industry as well as for the development of new ingredients and components: Distillation, Concentration, Drying.

Feed

Used for QC in the feed industry as well as for the development of new ingredients and components: Distillation, Concentration, Drying.