Mini Spray Dryer S-300

With the Mini Spray Dryer S-300, BUCHI solidifies its position as a global market leader for more than 40 years. The laboratory spray dryer combines outstanding product design with unique instrument capabilities to offer a superior user experience.

Nano Spray Dryer B-90 HP

With the Nano Spray Dryer B-90 HP, gently process the smallest sample amounts into submicron particles with minimal product loss. The user-friendly system improves productivity in areas where small particles make a big difference.

Inert Loop S-395

The safe way to spray dry organic solvents is to use the Inert Loop S-395 as the ideal accessory for your Mini Spray Dryer S-300. Its innovative design makes spray drying of organic solvents more environmentally friendly, cost-efficient and safe.

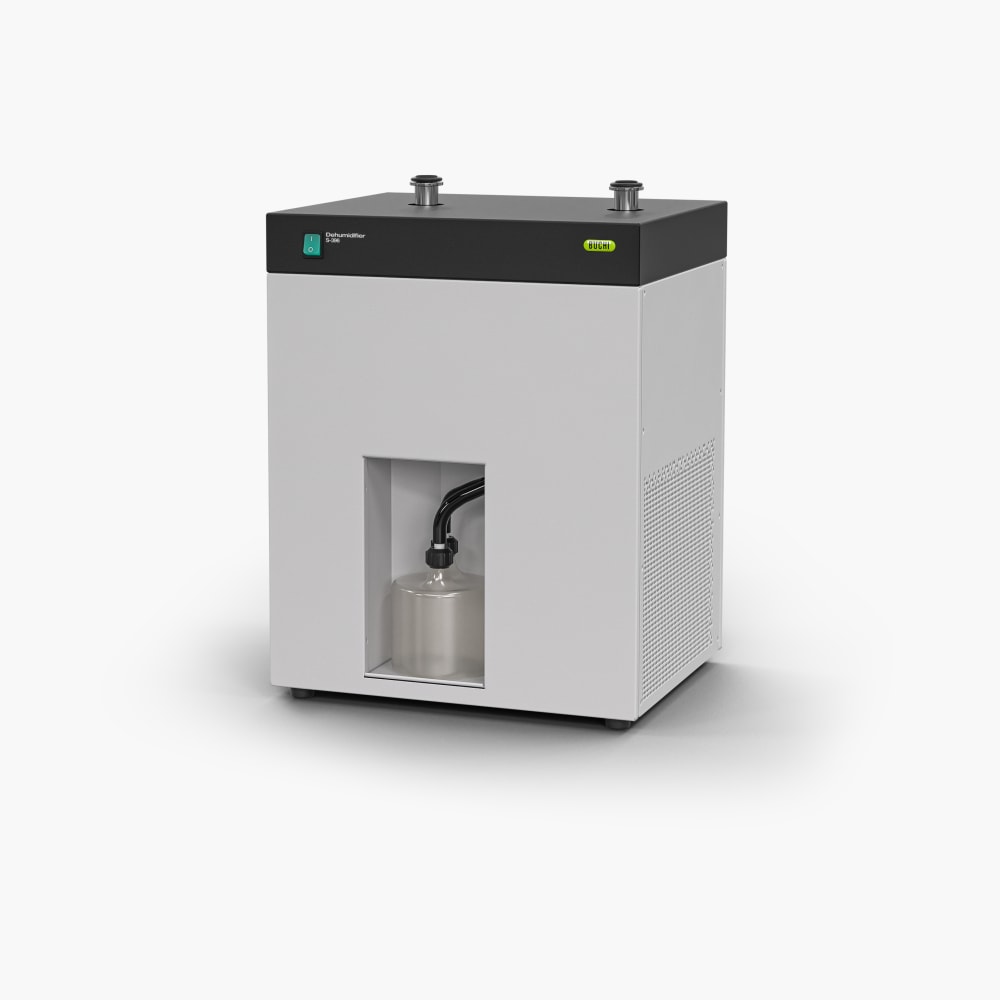

Dehumidifier S-396

The Dehumidifier S-396 is designed to provide dry air or to enable continuous work with water and organic solvent mixtures. The accessory improves your spray drying performance, while providing stable spray drying conditions.